Manufacturer of tools and technologies for non-destructive testing

"OKOndt GROUP" represents a group of companies with a more than 25-year experience in research, development and manufacture of NDT products for industrial clients all over the world, which endeavor to ensure a high-level operational safety, quality and reliability. Compared to other NDT suppliers, "OKOndt GROUP" provides highly reliable technical solutions at reasonable prices, allowing customers to maintain excellent operational stability at a minimum cost.

"OKOndt GROUP" is a registered trademark of the group of companies. Here is some of them:

PRP LLC (“Promprylad”)

PRP LLC (“Promprylad”)

Scientific industrial company. It is one of the leaders in developing and producing of innovative facilities for non-destructive material testing.

ULTRACON-SERVICE LLC

ULTRACON-SERVICE LLC

Manufacturer and NDT supply Company that offers a comprehensive range of products - from portable instruments and mechanized scanners to big automated ultrasonic testing systems.

"OKOndt GROUP" offers both a standard line of NDT instruments and custom equipment and probes built to individual customer specifications and for special materials. In addition to handheld devices, we also build large, integrated inspection systems, covering most NDT technologies. Our significant investment in research and development allows us to provide optimised solutions for all of our NDT customers.

Companies of "OKOndt GROUP" group supply NDT equipment to more than 70 countries

We produce various NDT instruments – from handheld flaw detectors to complex automated inspection systems, which are available worldwide through our network of distributors. Besides the sales, we provide post-sale and warranty services for all our products.

Our equipment utilises a variety of state-of-the-art methods and techniques for non-destructive testing, including ultrasound, phased array, time-of-flight diffraction (ToFD), electromagnetic acoustic (EMA), eddy current, eddy-current array, as well as a wide range of other conventional and custom approaches. We are focused on identifying the appropriate technique or combination of techniques to meet your specific needs.

Our flaw detectors are commonly used in the following industries:

- railway,

- energy & aerospace,

- petrochemical & metallurgy,

- machinery

The equipment produced by "OKOndt GROUP" improves the quality of our customers’ finished products and enhances the safety of their infrastructure.

Eddy-current techniques are applied in non-destructive testing of surface and sub-surface layers (detection of metal discontinuities), structure analysis, estimation of coat thickness, dimensions, chemistry, and heat treatment quality. Eddy current testing is based on the analysis of the interaction between external and eddy-current electromagnetic fields that are induced in test objects. Eddy currents are electric current loops which are excited in a conductor while changing the magnetic field that permeates it. The distinctive feature of eddy current inspection is that it can be performed without any contact between a flaw detector and a test object. The interaction is normally achieved at a short distance which is, nevertheless, sufficient for moving the probe relative to the object. This enables the procurement of excellent measurements even when test objects are moving at a high rate of speed.

NDT ultrasonic inspection techniques allow to detect the defects located at a considerable depth in various materials, products, and weld joints. Compared to other non-destructive testing methods, ultrasonic flaw detection has significant advantages: a high sensitivity to the most hazardous defects like cracks or incomplete penetration; high capacity; and the ability to supervise the testing directly from an operator’s workplace with no process interruption – all at low operational cost. Ultrasonic examination is applied in a wide range of industries: energy, heavy machinery, railway, ship building, and the chemical sector. Hundreds of thousands of meters of structural welds, tens of thousands of pipe joints, boiler units, rail weld joints, as well as the quality of pressurised tank parts, forgings, tubes, rolled plates and other products are annually inspected by means of ultrasonic NDT techniques.

The electromagnetic acoustic (EMA) technique is a combined method of non-destructive testing based on three effects of interaction between magnetic fields and the test object: magnetostrictive, magnetic, and electrodynamic effects. The electrodynamic effect is caused by inducing eddy currents in a conductive material that interact with constant magnetic field, which, in its turn, initiates crystal-lattice vibrations (whereas elastic acoustic oscillations occur due to mechanical stresses). EMA transducers are capable of generating horizontally & vertically polarised, longitudinal, shear, Lamb, and Rayleigh waves. Horizontally polarised shear waves have minimum attenuation, diffraction, and metal structure refraction coefficients. The EMA technique allows for non-contact ultrasonic examination of material homogeneity at high temperatures.

Product categories

Upcoming Events

13th ECNDT Conference (ECNDT 2023)

3-7 July 2023

Centro de Congressos de Lisboa (CCL)

Praça das Indústrias

1300-307 Lisbon, Portugal

We will be glad to meet you there.

Appoint a meeting!

Railway Interchange 2023 (RI 2023)

1-4 October 2023

Indianapolis, IN, USA

Largest combined railway exhibition and technical conference in North America!

Our Booth Number is 4055

We are pleased to invite you to visit our booth!

OKOndt GROUP in REMSA Exhibit Hall of Indana Convention Centre

20th WCNDT (South Korea)

27-31 May 2024

20th World Conference on Non-Destructive Testing (WCNDT 2024) in in Seoul, South Korea.

Get to know our NDT equipment at the booth CO2.

Appoint a meeting!

Meet us at world famous Annual Conferences and Exhibitions

ASNT Annual Conference

(Houston, USA)

WCNDT Exhibition

(Munich, Germany)

Aerospace Event

(Filton, Bristol, UK)

ECNDT

(Prague, Czech Republic)

NDE

(Pune, India)

WCNDT

(Durban, South Africa)

Together with our partners we develop new NDT techniques and their application standards

«OKOndt GROUP» organizes annual international conference for discussing and implementing those initiatives in different industry fields.

We are the active members of international societies

Applications of non-destructive testing

In-Service Inspection of Aircraft Blocks Using Eddy Current Flaw Detector EDDYCON C

The following are the examples of "Boeing" company testing methods implementation with a new EDDYCON C eddy current flaw detector. For regular flights many airlines use "Boeing 737-300, 737-400, 737-500" aircrafts. These aircrafts operational NDT is carried out in accordance with the manual of "Boeing" company (NDT Manual for Boeing 737)

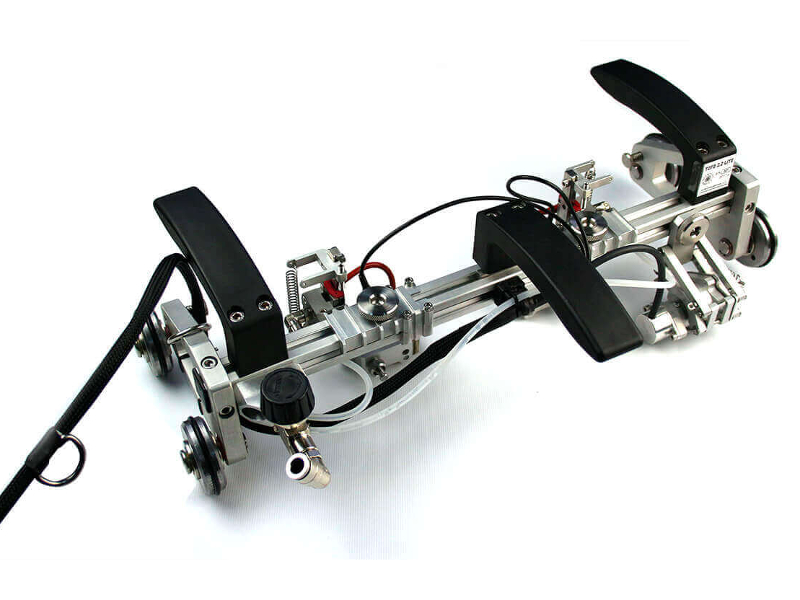

The system of automated ultrasonic testing of railway axles SAUT «Uniscan – Luch OS–4»

Service life and reliability of railway wheel pairs operation are largely dependent on quality of their components, one of which is the railway axle. Therefore, during manufacture of railway axles it is required to conduct products regular non-destructive testing at all stages of their manufacture for in-time detection of unacceptable defects.

Experience of ULTRASONIC testing of Boeing 737 -300, -400, -500 planes structure elements in operating conditions

During technical maintenance of BOEING 737 -300, -400, -500 planes (hereinafter referred to as B737) ultrasonic technique of non-destructive testing is widely used (hereinafter referred to as UST).