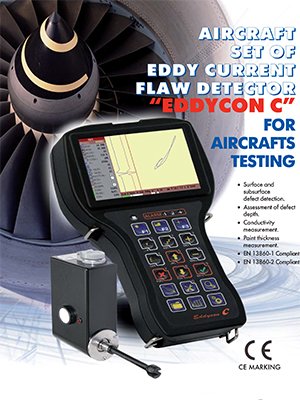

The EDDYCON C&CL portable eddy current flaw detectors are flagships in our eddy current instrument family. They combine the best features of earlier predecessors, being furnished with 4.3" (Eddycon C) or 7.2" (Eddycon CL) display and functional buttons for immediate access to any menu of the instrument, which would meet requirements of the most demanding user.

Now Eddycon available in two versions:

Eddycon C

Eddycon CL

EDDYCON C&CL eddy current flaw detectors are intended for:

- detection of surface cracks in various parts;

- finding of cracks in holes and multi-layered structures with the help of rotary scanners;

- recognition of sub-surface flaws in non-magnetic conductive materials;

- evaluation of non-magnetic material conductivity, and paint coating thickness;

- welding quality testing by eddy current.

These devices allow to perform full eddy current testing of aircraft parts in accordance with the requirements of the regulations AIRBUS A318 / A319 / A320 / A321 NONDESTRUCTIVE TESTING MANUAL NTM, BOEING 737 NON-DESTRUCTIVE TEST MANUAL.

Eddycon C&CL benefits:

- easy-to-operate due to user-friendly intuitive interface;

- light and sound alarms;

- strict compliance with EN-15548;

- saving of more than 1000 settings and test results to the flaw detector memory;

- data communication to PC via USB flash drive;

- specialty software for viewing test results and printing out test reports;

- application-dependent software for data displaying on a PC;

- software upgrade using USB flash drives;

- evaluation of flaw depth;

- review of saved defectograms on the display of eddy current flaw detector;

- quick-release Li-Ion battery for continuous:

- 7-hours operation for Eddycon C;

- 10-hours operation for Eddycon CL;

- lightweight – only 0.9 kg (Eddycon C) and 1.85 kg (Eddycon CL).

Portability and lightweight

Due to small size of the eddy current equipment, an operator can set it up with one hand only. The device is furnished with a side strap, which allows for a firm hold of the flaw detector either in right or left hand, while its narrow width helps easily reach any button on the keypad. Thanks to its lightweight, an operator can perform eddy current testing for a long period of time, not being tired.

Display

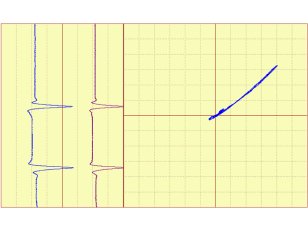

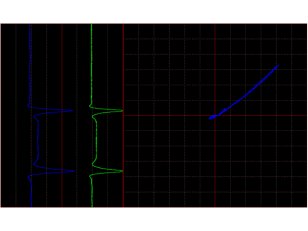

4.3" (Eddycon C) and 7.2" (Eddycon CL) TFT color displays with 800×480 pixels resolution ensures a high-definition picture on the screen. The screen has several display modes, such as light, dark and standard.

Different modes of full-screen presentation

a) Menu+XY+A(t)

b) Menu+XY

c) Menu+A(t)

d) XY+A(t)

e) XY

f) A(t)

Navigation

Elaborated keypad design gives a quick access to any menu of the flaw detector by pressing a single key only!

- TESTING menu - main operating mode of the flaw detector;

- MEMORY menu - is used to save/download the settings and test results;

- SETTINGS menu - basic settings of the flaw detector;

- VIEW menu - allows viewing test results saved to the flaw detector’s memory;

- CALIBRATION menu - serves to create calibration curves for more precise evaluation of flaw depth.

Industrial applications:

- Aerospace

eddy current inspection of aircraft engineering parts (wheel disks, skin, turbine blades, multi-layered structures, various holes, etc.);

- OIL & GAS

eddy current crack detection of pipelines, turbine blades of gas-distributing stations (GDS), pressure vessels, etc.;

- Chemical

examination of pipelines, industrial tanks, etc.;

- Power

non-destructive testing of steam generator tubes and headers by eddy current bobbin probes, etc.;

- Heavy machinery

eddy current inspection of bars, wire, steel structures, mill rollers, plates, etc.;

- Railway

eddy current crack detection of railway parts and car units (wheelsets and axle boxes bogies of freight, refrigerator and passenger cars, automatic coupler, etc.).

| MODEL | ||

| EDDYCON C&CL (International version) | EDDYCON C&CL (English version) | |

| Probe connector | Lemo 12-way (Reflection, Bridge); Lemo 00 (single coil) | Lemo 16-way (Reflection, Bridge); Lemo 00 (single coil) |

| Encoder connector | Lemo 08-way | |

| Compatible with the following rotary scanners | SVR-02, SVR-04, MiniDrive (GE) | SVR-03, SVR-05, MiniMite (OLYMPUS) |

| Evaluation of flaw depth | ✔ | |

| Operation with linear encoder | ✔ | |

| Dual-frequency & mix-modes | ✔ | |

| Measurement of electrical conductivity and coating thickness | ✔ (Eddycon CL) | |

| Quick-release battery | ✔ | |

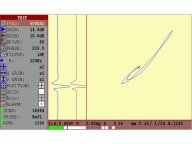

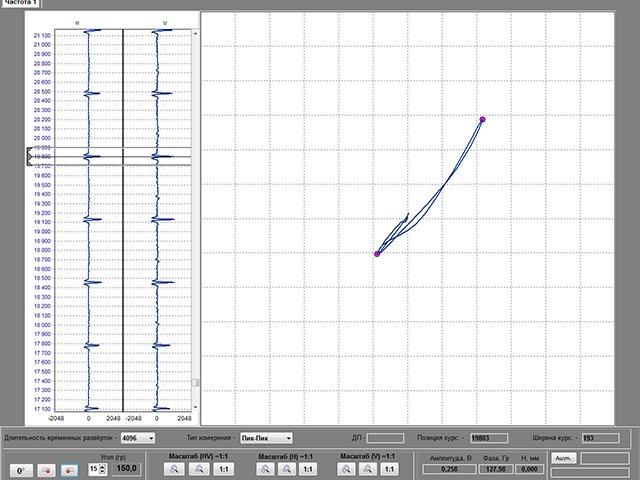

Specialized application-dependent software of Eddycon C multipurpose eddy current flaw detector serves for processing test results, followed by generating and printing out test reports. The software program allows working with the saved data on PC.

Main advantages of the program are as follows:

- Intuitive user-friendly interface;

- Easy viewing of test results for each frequency mode (Frequency №1, Frequency №2 & Mix);

- Generation and storage of electronic reports;

- Data output for each detected flaw, namely:

- flaw location coordinate on a defectogram (if using an encoder);

- signal amplitude and phase;

- flaw depth.

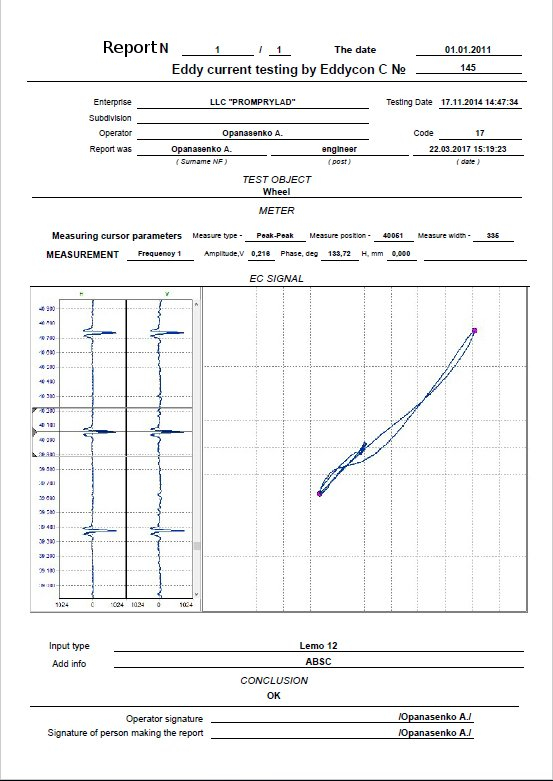

The resulting electronic report contains all basic data on test performed, such as:

- name of company, NDT department and inspector who performed the test;

- description of test object;

- all setting parameters of the instrument at the time of testing;

- parameters of signals coming from defects (amplitude, phase, depth);

- representation of the signals from defects in a complex plane or strip chart);

- inspection date;

- possibility to create reports of other types, when approved by the Customer.

| Housing | |

| Overall dimensions | Eddycon C 230 mm × 135 mm × 98 mm (9.5" × 5.3" × 4.4" ) Eddycon CL 256 mm × 156 mm × 80 mm (10" × 6.1" × 3.1") |

| Weight | Eddycon C up to 0.9 kg Eddycon CL up to 1.85 kg |

| Applicable standards | СЕ, EN-15548 |

| Supply mains | 100 V to 240 V, 50 Hz - 60 Hz |

| Inputs & outputs | 2.0 USB-port (hub), Ethernet (Lemo 4-way), headphones (Lemo 4-way) |

| Keypad | English, international (icons) |

| Operation conditions | |

| Operation temperature | -20 to +50 |

| Storage temperature | -20 to +50 |

| IP rating | Eddycon C IP 64 Eddycon CL IP 64 |

| Battery | |

| Type | Li-Ion 12В/4500 mA·h (Eddycon C) Li-Ion 12В/10000 mA·h (Eddycon CL) |

| Operation time | up to 7 hours (Eddycon C) up to 10 hours (Eddycon CL) |

| Display | |

| Display size | Eddycon C 93.6 mm ×56.16 mm; 4.3" Eddycon CL 156 mm ×94 mm; 7.2" |

| Type | Color TFT (800×480 pixels) |

| Display modes | Normal, full-screen; three color schemes |

| Grid | Three types: coarse, fine, polar |

| Connectivity and data storage | |

| PC software | Test results processing program |

| Data storage | MicroSD 4 Gb internal memory card (up to 64 Gb as an option); |

| ET specifications | |

| Frequency range | 10 Hz to 16 MHz |

| Gain | 70 dB |

| Probe supply voltage | 0.5 V; 1V; 2V; 4V; 6V |

| Additional gain | 30 dB |

| Phase rotation | 0 to 359.9 |

| Digital scale | 1/16 to 16, with a step of 6 dB |

| Test frequency | 1 to 11 kHz |

| Signal indication time | 0.1 s; 0.3 s; 0.5 s; 1 s; 2 s; 3 s; 4 s; 5 s; 8 s |

| Filter | Low-pass: 1 to 5 500 Hz High-pass: 1 to 5 500 Hz Bandpass Averaging |

| Connected probes | Single coil Reflection Bridge |

| Probe connector | Lemo 00, Lemo 12-way / Lemo 16-way |

| Signal display modes | Complex plane – X(y); Time base – X(t), Y(t); Dual-frequency mode |

| Threshold level types | Circle, Threshold, Sector, Trapezium |

| Multi-frequency operation | Dual-frequency multiplexing; Independent control of both frequencies; Mix of two frequencies (F1 - F2, F1 + F2) |

| Eddy current flaw detector Eddycon C & CL (Lemo 12) |

| Eddy current probe SS340K09DA0 |

| Connection cable Lemo 12 – Lemo 04 (Lemo 04, connector type 0В, Reflection) |

| Charger |

| Calibration block RS 2353/1-3N-Fe |

| Software for operation with PC |

| Operating Manual EC.14327992.02.13 OM |

| Quick start guide |

| Operating for Charger |

| Registration certificate for reference standard RS 2353/1-3N-Fe |

| Bag |

| Registration certificate for ECP |

| Eddy current flaw detector Eddycon C & CL (Lemo 16) |

| Eddy current probe SS340K09DA0 |

| Connection cable Lemo 16 – Lemo 04 (Lemo 04, connector type 0В, Reflection) |

| Charger Mascot Type 2542 |

| Calibration block RS 2353/1-3N-Fe |

| Software for operation with PC |

| Operating Manual EC.14327992.02.13 OM |

| Quick start guide |

| Operating Manual Mascot 2542 |

| Registration certificate for reference standard RS 2353/1-3N-Fe |

| Bag |

| Registration certificate for ECP |

| № | Description | Notes |

| CABLES | ||

| 1.1 | Connecting cable Lemo 12 – Lemo 12 (for rotary scanner SVR-04), 70 in. (1800 mm) | For rotary scanners |

| 1.2 | Connecting cable Lemo 12 – Lemo 04 (for Reflection type probes), 70 in. (1800 mm) | For Lemo 4-way probes (EGG.0B) |

| 1.3 | Connecting cable Lemo 12 – Lemo 04 (for Bridge type probes), 70 in. (1800 mm) | |

| 1.4 | Connecting cable Lemo 12 – Lemo Triax (for Reflection type probes), 70 in. (1800 mm) | For Lemo Triax probes (ERN.0S650.CTA) |

| 1.5 | Connecting cable Lemo 12 – Lemo Triax (for Bridge type probes), 70 in. (1800 mm) | |

| 1.6 | Connecting cable Lemo 12 – Lemo 04 (for Conductivity probes), 47 in. (1200 mm) | For CP-13 (conductivity probe) |

| 1.7 | Connecting cable Lemo 00 – Microdot/М5 (for single coil probes), 70 in. (1800 mm) | For probes with Microdot connector |

| ROTARY SCANNERS | ||

| 2.1 | Rotary scanner SVR-04 | Lemo 12-way connector |

| BATTERY | ||

| 3.1 | Replaceable battery pack | |

| 3.2 | Adapter for charging the replaceable battery pack | |

| № | Description | Notes |

| CABLES | ||

| 1.1 | Connecting cable Lemo 16 – Lemo 16 (for rotary scanner SVR-05), 70 in. (1800 mm) | For rotary scanners |

| 1.2 | Connecting cable Lemo 16 – Lemo 04 (for Reflection type probes), 70 in. (1800 mm) | For Lemo 4-way probes (EGG.0B) |

| 1.3 | Connecting cable Lemo 16 – Lemo 04 (for Bridge type probes), 70 in. (1800 mm) | |

| 1.4 | Connecting cable Lemo 16 – Lemo Triax (for Reflection type probes), 70 in. (1800 mm) | For Lemo Triax probes (ERN.0S650.CTA) |

| 1.5 | Connecting cable Lemo 16 – Lemo Triax (for Bridge type probes), 70 in. (1800 mm) | |

| 1.6 | Connecting cable Lemo 16 – Lemo 04 (for Conductivity probes), 47 in. (1200 mm) | For CP-13 (conductivity probe) |

| 1.7 | Connecting cable Lemo 00 – Microdot/М5 (for single coil probes), 70 in. (1800 mm) | For probes with Microdot connector |

| ROTARY SCANNERS | ||

| 2.1 | Rotary scanner SVR-05 | Lemo 16-way connector |

| BATTERY | ||

| 3.1 | Replaceable battery pack | |

| 3.2 | Adapter for charging the replaceable battery pack | |