ETS2-77 purpose

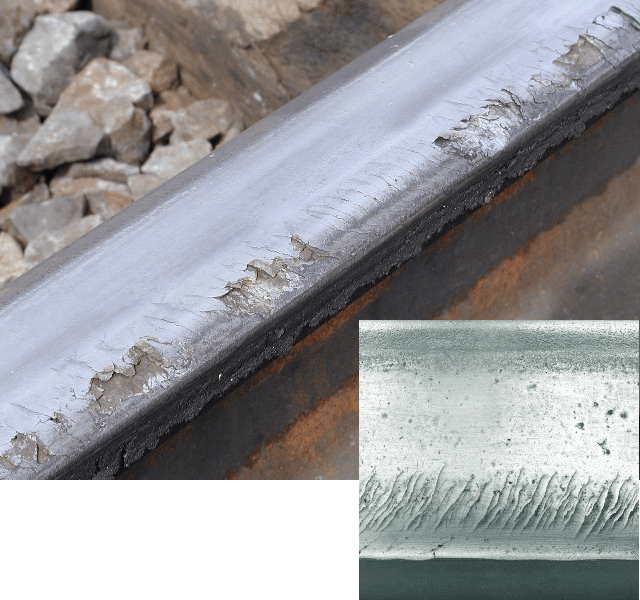

Eddy current method application at the active face control and the rolling surfaces of the rails allows to perform not only evaluation of the vertical damage depth but the localisation of the areas with surface marks, such as:

- transversal fatigue cracks (International Defect Code (UIC) 211);

- quenching cracks (International Defect Code (UIC) 2223);

- active face delamination (International Defect Code (UIC) 2222);

- wheels sliding areas (International Defect Code (UIC) 225).

Performing the rail head vertical damage evaluation enables to decide if the grinding machines application is actual, or whether the damaged area replace shall be provided. This allows to significantly cut the time and financial expenditure.

APPLICATION

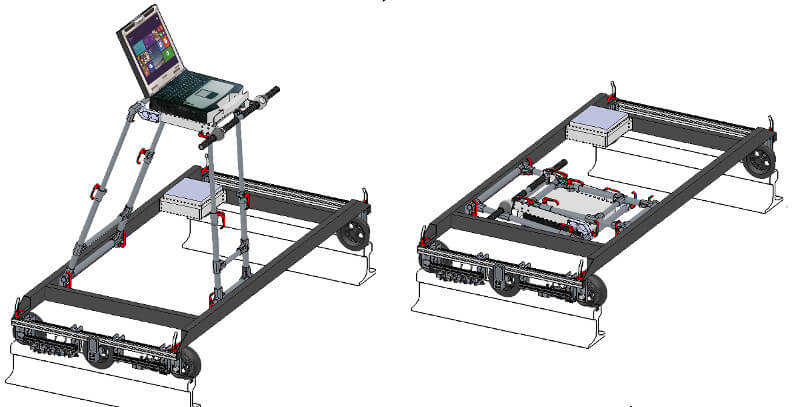

- possibility to control the rail track and the track switch;

- selective control of the separate rail track areas;

- post grinding machines control;

- all main rail profiles control S49 (49E1), UIC54 (54E1), UIC60 (60E1).

Eddy current rail inspection equipment ETS2-77 advantages

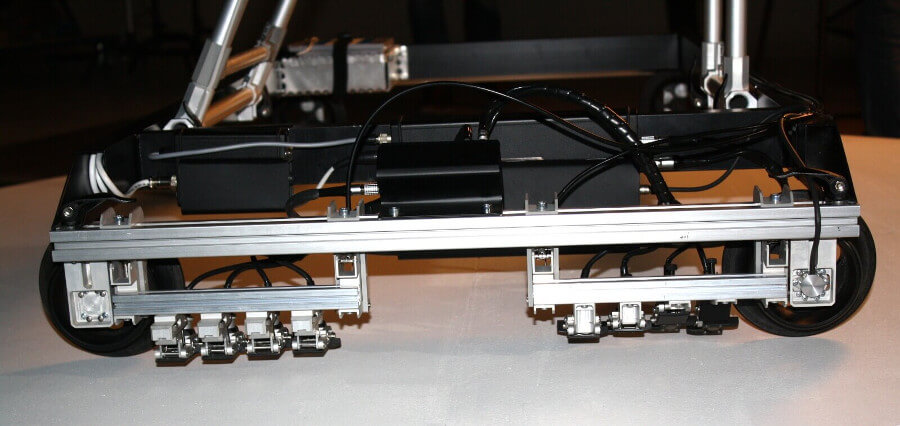

- light aluminum frame;

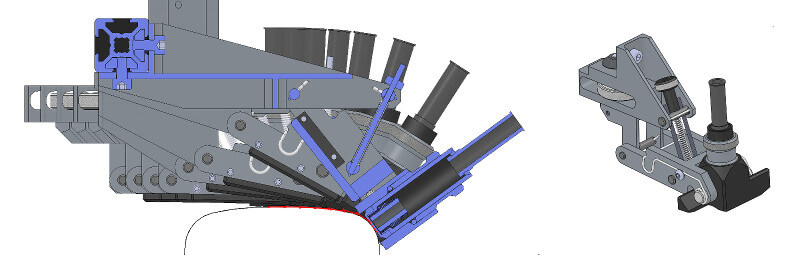

- specialized abrasion-resistant ECPs allow to evaluate the oblique cracks with up to 3 mm vertical damage depth;

- 8 ECPs application allows to perform the control of the whole head rail surface in one run;

- individual spring-mounted suspension of each ECP;

- possibility of fast lifting of the scanners during the transfer from one testin area to another;

- individual adjustment of ECP position;

- operating time – not less than 8 hours;

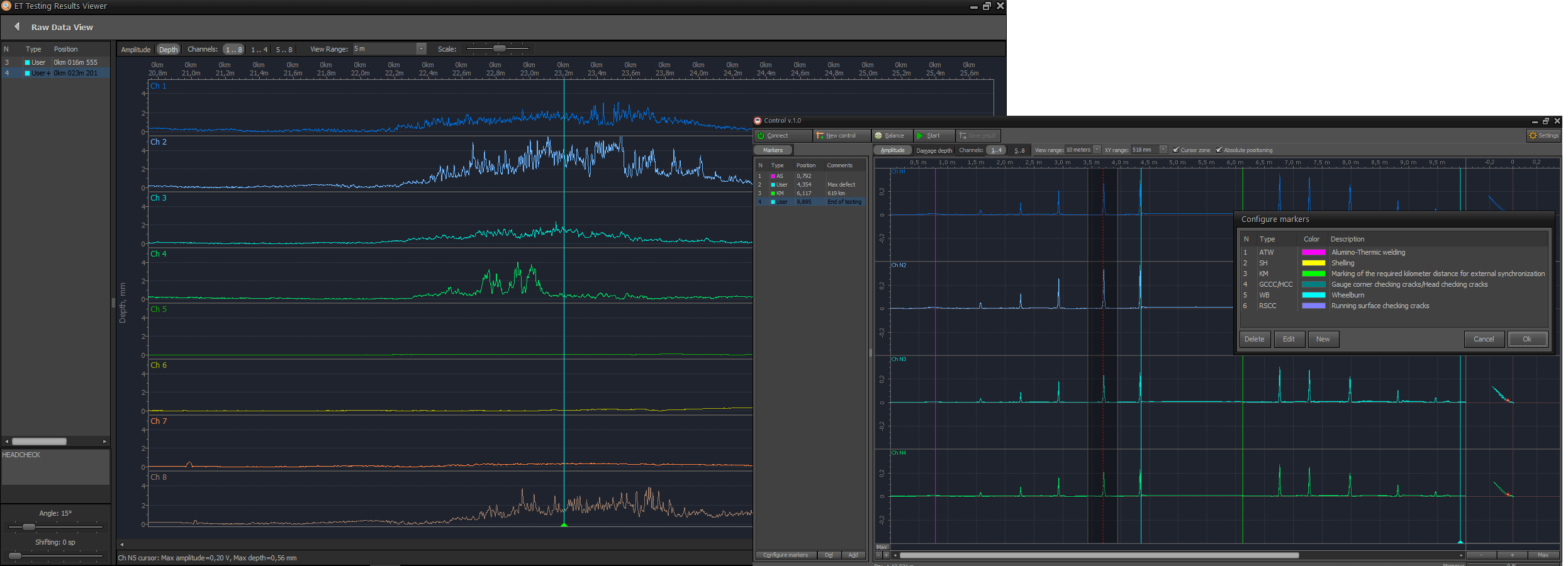

- specialized software for setting up, testing and inspection results review

SPECIFICATION

| Model | ETS2-77 |

| Flaw detector type | mechanized |

| Overall dimensions in the stowed position | 1730 mm × 900 mm × 350 mm |

| Eddy-current channel | Eddycon D |

| Scanning device |

|

| ECP quantity | 8 |

| Tested area by one ECP | 6 mm |

| ECP protection from the abrasion and damage | Ceramic protective cover |

| Test velocity | Up to 2 m/s |

| Alarm | Visual |

| Specialized software |

|

| Operating time | 8 hours |

| Record and data storage | + PC hard disk |

| Working PC | Industrial one, IP rating 65 |