VD-ОKО-01 Purpose

VD-ОKО-01 universal multi-channel eddy current flaw detector is intended for solving a wide range of eddy current flaw detection tasks in such branches of industry as:

- AIRCRAFT

testing of aeronautical engineering parts (wheel disks, skin, turbine blades, multilayered constructions etc.); - RAIL TRANSPORT

testing of rail components and car units (parts of wheel pair and axlebox unit, load trolleys, refrigerated carriages and coaches, automatic coupler etc.); - OIL-AND-GAS

testing of pipelines, pressure vessels etc.; - CHEMICAL

testing of pipelines, industrial vessels etc.; - POWER

testing of steam generator pipes by I/D ECP, collectors etc.; - ENGINEERING

testing of rods, wire, metalwares, forming rolls, sheet metals, metal parts of bearing structures etc.

FLAW DETECTOR ADVANTAGES

- high efficiency due to flaw detector multi-channeling;

- possibility of flaw detector application during mechanized and automated testing execution;

- exclusion of human factor influence (if it is used as a part of mechanized testing system);

- possibility of the evaluation of defect depth and length, and also LED and sound flaw alarm;

- operation simplicity due to the intuitive interface;

- registration of all testing results and extended capacities of data analysis.

DISTINCTIVE FEATURES OF THE FLAW DETECTOR

- large color high-contrast TFT display;

- ALARM system: 4 three-color LEDs, sound alarm;

- various scanning units manipulation;

- USB slave;

- possibility of up to two encoders connection;

- possibility of software application for different testing tasks: testing of pipe bodies, rolled metals, wheel pairs, rods and wires etc.

TECHNICAL SPECIFICATION AND SERVICE FUNCTIONS OF THE INSTRUMENT

- flaw detector sensitivity threshold on artificial defects, such as "slit" on the calibration block: length – 2 mm; depth – 0,05 mm; opening – from 0,02 mm;

- operating frequency setup range – from 50 Hz to 2 МHz;

- generator output voltage (double amplitude) – from 0,5 V to 16 V;

- adjusted gain range – 52 dB;

- digital filtering, 3 filter types: Bandpass, Differential, Averaging;

- electronic instrument duct consists of 1 physical channel with possible multiplexing using outer commutators;

- possibility of 4 multiplex units connection;

- connection of up to 32 channels to one multiplex unit;

- external synchronization;

- LED (4 LEDs) and sound flaw alarm;

- automatic (phase) tuning out from the influence of operating gap and inhomogeneity of electromagnetic properties of the testing object;

- possibility of connection and operation of ECP of the following types:

- differential ECP;

- differential ECP connected according to the bridge scheme;

- differential transformer ECP with grounded centerpoint;

- differential transformer ECP;

- absolute (parametric) ECP;

- absolute transformer ECP.

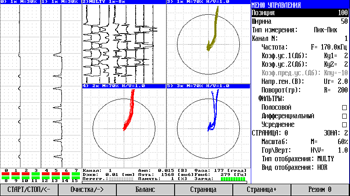

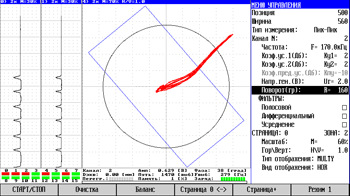

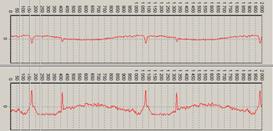

- eddy current signal display in various views:

- display of 4 areas on one page;

- MULTY mode – band charts each of which corresponds to a specific channel are displayed in one area;

- complex plane (XY) – allow to detect defects among interferences by analyzing the signal form;

- 2D- mode of two-dimensional defect display;

- bar diagram (BAR).

|  |  |  |

- time of flaw detector operation mode setup – up to 1 minute;

- storing of instruments setups and testing results on compact-flash memory card;

- mode of two-way connection with PC via USB port (for inputting the information from the flaw detector memory into PC and possibility of this data printing as well as setups loading from PC into the flaw detector memory);

- encoder connection option;

- four independent frames of automatic flaw alarm (ALARM) for each display area;

- evaluation of defect depth and length;

- channels mixing option;

- possibility of signal display color selection for each channel and channels mix separately;

- autozap function;

- built-in clock and calendar;

- screen backlight;

- screen brightness control;

- reception path overload check;

- check of flaw detector memory fill;

- storage battery discharge level indication;

- friendly multi-language interface;

- time of continuous flaw detector operation with the fully charged storage battery – at least 8 hours;

- flaw detector is powered from the following sources:

- EPU with rated voltage of 12 V and rated capacity of 9 А×h;

- AC mains with voltage from 187 V to 242 V, with frequency (50 ± 1) Hz.

PERFORMED CONFIGURATIONS

By creating special scanners for VD-ОKО-01 instrument, it is possible to solve effectively the flaw detection tasks of metal units and parts in various branches of industry. As a result, VD-ОKО-01 flaw detector complete with scanners is a universal mechanized complex of non-destructive testing.

Today, VD-ОKО-02 eddy current flaw detector, together with scanners, solves the following tasks of eddy current flaw detection:

The series of VD-SCANNER multi-channel scanners on the basis of VD-ОKО-01 flaw detector is intended for carrying out mechanized eddy current testing of radial surfaces with different curvature radii in order to detect surface defects, such as longitudinal and transverse cracks, folds, scabs etc. | |

Production crack of 0,76 mm in depth and up to 60 mm in length detected during straight-line-seam pipe testing |  Execution of main pipe body testing using VD-ОKО-01 flaw detector complete with VD-SCANNER 028-mm channel scanner enabled to evaluate the pipe damage rate and its further operability |

SKV-GP scanners family is intended for performing 100% mechanized testing of fillet transitions with various curvature radii on radial surfaces. | |

Signal from crack on the fillet transition with radius of 25 mm and depth of 0,54 mm detected during field inspection of forming roll |  Carrying out of 100% eddy current testing of forming rolls using VD-ОKО-01 flaw detector and special scanning units allows to evaluate the damage rate of both roll working surface and fillet transitions |

ADDITIONAL SOFTWARE

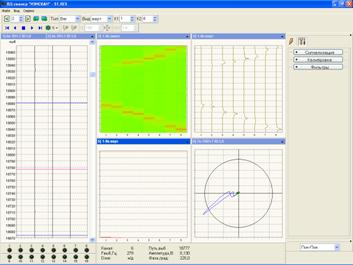

Speciality application-dependent software for processing the testing results of VD-ОKО-01 universal eddy-current flaw detector serves for functionality extension and instrument operation ease increase. This program provides operation with the data stored on PC.

Main advantages of program application are:

- convenient view of testing results by each channel;

- possibility of automatic scrolling of the stored defectogram at different speeds;

- possibility of the displayed results type changing, namely the display of raw data in the mode:

- MULTY;

- 2D;

- XY.

- digital testing results processing with the usage of filters: Bandpass, Differential, Averaging;.

The data received during inspection can be processed using digital filtering algorithms. This may improve signal/noise ratio, single out useful signal component or reject signals from interfering factors (zero drift, arm shake, testing object geometry change etc.).

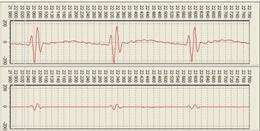

Examples of digital filtering application in signals processing program:

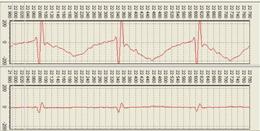

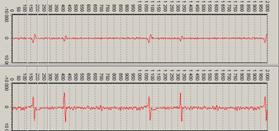

Averaging filter

Averaging filter operation is similar to lowpass filter operation, its aim is to remove high-frequency noise present in the signal and, thereby, increase signal/noise ratio. As a rule, it is applied when operating at high gains.

Pickup signal |  Signal after using Averaging Filter |

Bandpass filter

Signals received during testing of rotary cylinder sleeve with further processing by bandpass filter allow to suppress lowpass harmonic component related to the sleeve rotation.

Pickup signal |  Signal after using Bandpass Filter |

Differential filter

In a number of cases when the signal from the interfering factor has a pronounced periodic character, it can be efficiently eliminated (or minimized) with the help of differential filter.

Pickup signal |  Signal after using Differential Filter |

- filters parameters setup;

- ALARM unit setup;

- calibration;

- zooming, preset area changing, convenient diagrams scrolling;

- defect depth evaluation;

- output of the table with detected defect data, notably:

- channel number via which ALARM went off;

- defect position coordinate;

- amplitude and phase of signal having transcended the threshold level;

- defect depth.

|  |  |

- printing of eddy current testing report with the display of signals from defect.

|

|

Probes for flaw detector:

| Main specifications | |

| Overall dimension of flaw detector without a handle and with one eddy current unit and power unit | no more than 330 mm x 180 mm x 140 mm |

| Weight of flaw detector with one eddy current unit and power unit | no more than 6 kg |

| Keyboard | Russian |

| Languages | Russian |

| Number of eddy current units | 4 |

| Number of channels in eddy current unit | 32 channels |

| Connectors types | Lemo-14, DB-15 |

| Data storage | flash card |

| Independent power source | NiMH storage battery of rated voltage 12 V and rated capacity 9 А∙h |

| Operation time | 8 hours |

| Power supply | AC mains of voltage (220 В ± 10%) and frequency (50 ± 1) Hz |

| Flaw detector electric power consumed from AC mains | no more than 30 V·А |

| Time of flaw detector operation mode setup | no more than 1 min. |

| Display type | NL8060BC21-03 (800×600 pixels) |

| Screen dimensions (width, height, diagonal) | 170 mm × 130 mm, 214 mm |

| Warranty | 1 year |

| Inputs/outputs | |

| USB Port | USB slave, USB host |

| RS – 232 | available |

| PS/2 | two inputs |

| Trigger I/O | available |

| Headphones | available |

| Encoder output | single-coordinate encoder |

| Main metrological performances | |

| Protection level in operation | IP 64 |

| Ambient temperature | from minus 100 to +400 ºС |

| Atmospheric pressure | from 84 to 106,7 kPa |

| Relative humidity | (93 ± 3) % at the temperature of 25 ºС |

| Flaw detector in shipping package is resistant to the influence of |

|

| Flaw detector retains its parameters when it is influenced by electromagnetic interferences which do not exceed the following norms |

|

| Full average flaw detector lifetime | no less than 10 years |

| Pulser | |

| Output voltage (double amplitude) | 0,5; 1; 2; 4; 8; 16 |

| Operating frequencies range | from 50 Hz to 2 МHz |

| Synchronization type | internal, from encoder, from rotary ECP |

| Receiver | |

| Gain | from 0 to 40 dB with a step of 1, 10 dB |

| Input signal | no more than 0,5 V from peak to peak |

| Digital filters | 3 digital filters: Bandpass, Averaging, Differential |

КОМПЛЕКТ ПОСТАВКИ ДЕФЕКТОСКОПА ВИХРЕТОКОВОГО МНОГОКАНАЛЬНОГО ВД-132-К-IIIУ-ОКО-01