UD4-76(TOFD) Purpose

UD4-76 universal ultrasonic flaw detector-tomograph with a large high-contrast TFT display is intended for products testing for detection of defects, such as discontinuity and inhomogeneity of materials, goods and in-process goods, welded joints, measurements of signals amplitude ratio from defects, of depth and their depth coordinates. Tomograph function enables to display and store testing results in the form of B-scans with reference to the scanning path. Flaw detector also solves the task of items thickness measurement at one-way access. Several operating modes for DGS diagrams are provided too, what makes it possible to define conveniently and quickly equivalent defects dimensions.

UD4-76 universal ultrasonic flaw detector is adapted and totally meets the requirements of regulatory documentation valid in various industrial sectors, such as nuclear power engineering, metal production, pipe industry, rail transportation etc.

FLAW DETECTOR ADVANTAGES

For carrying out the testing of different parts, an individual approach is required for solving each separate task. "Promprylad" scientific production company has great experience in this field and offers the customer:

- special operating modes performed on the basis of the instrument software package and adapted to the customer's needs (among them there are: "Peak" mode, "Reflections marking" mode, automatic algorithms of probe calibration, modes of automatic DGS-diagrams and TCG-curves plotting, data storage in the form of RF B-scan, rendering of "corrosion map" ("thicknesses map") and other);

- flaw detector ergonomics when working with the object (large high-contrast TFT-display, small instrument weight, convenient menu, presence of automatic sound and light alarm of defects at three levels: search, registration, acceptance);

- individual delivery set which includes the set of ultrasonic probes adapted to the testing of a certain range of welded joints and other ultrasonic testing objects.

DISTINCTIVE FEATURES OF THE FLAW DETECTOR

- large color high-contrast TFT display;

- metal protective case;

- ALARM system: 3 three-color LEDs, sound alarm;

- convenient menu navigation;

- various probes types operation;

- possibility of sound comments recording for all stored data types;

- USB slave;

- encoder connection;

- software application for different testing tasks;

- various A-scan display forms: RF/full wave/+half wave/-half wave/envelope;

- dynamic change of generating path characteristics depending on the switched-on frequency filters;

- information display forms: А-scan, B-scan, orthogonal views, corrosion map.

INSTRUMENT SERVICE FUNCTIONS

- Availability of two independent measurement gates with the defect alarm system (sound and light) by every gate. In addition, every gate has:

- three going-off levels: "ACCEPTANCE"; "REGISTRATION"; "SEARCH"; are marked on flaw detector screen in "RED", "BLUE" and "GREEN" color. The colors of light ALARM by every gate correspond to them.

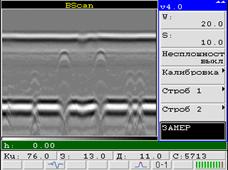

| Mode of time of flight diffraction (TOFD) | |

| It is based on the time measurement of propagation of waves diffracted from the defect boundaries. TOFD technique is performed with two probes, operating by tandem technique. It is intended for manual testing of butt-welded joints, plane surfaces and pipes. To ensure a constant distance between index points of the given probes and their orientation in relation to each other, a manual scanning device is used. Function of information presentation about the position of ultrasonic probes with the help of an encoder is also performed. |  |

The main advantage of this technique is more precise determination of coordinates and dimensions of discontinuities, including cracks. Today TOFD technique is used for the testing of objects quality instead of traditional methods: radiation and ultrasonic echo-pulse techniques. Such defects as discontinuities, incomplete fusion, cracks, porosity and slag inclusions can be detected and their characteristics can be determined by means of this technique.

TOFD mode provides:

- testing of the whole weld volume per one scanning cycle;

- testing of various dimension-types of welded joints;

- determination of defects dimensions without regard to the amplitudes of diffracted signals;

- high sensitivity to all types of defects regardless of their orientations.

Functional capabilities:

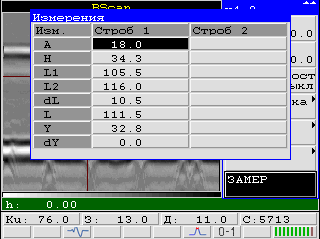

- storage and display of the data in the form of A-scan and RF B-scan;

- viewing of the testing results in the form of А-Scan and RF B-Scan;

- "calibration" mode;

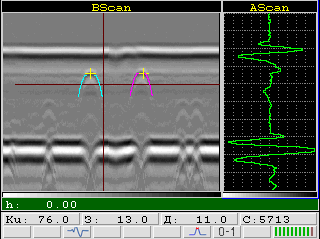

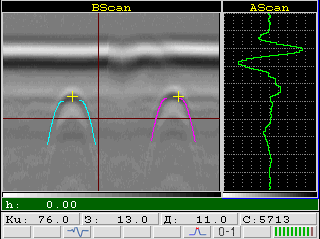

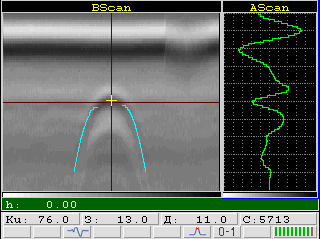

- usage of two standard cursors or two hyperbolic cursors;

- data scaling with reference to the first or second cursor;

- determination of the type and dimensions of defects in vertical plane and scanning plane when using hyperbolic cursors;

- time controlled gain (TCG) mode;

- DAC amplitude curves mode;

- "Reflection marking" mode;

- "Peak" mode;

- measurement of equivalent defect dimensions (DGS diagrams);

- SAFT mode;

- «corrosion mapping» and «thickness mapping»;

- RF signal display;

- mode of special interface;

- mode of communication with PC.

ADDITIONAL SOFTWARE

Ultra UDх-7х – the program intended for processing testing results of UD4-76 ultrasonic flaw detector and serves for functionality extension and increase of instrument operation comfort. The present program assures operation with the data stored on PC.

| Parameters | Units | Values |

| Max. scan range | inch | 236,22 |

| mm | 6000 | |

| Min. scan range | inch | 0,039 |

| mm | 1 | |

| Velocity in the material | inch /µs | from 0,0025 to 0,0375 |

| m/s | from 1000 to 15000 | |

| Scan delay | inch | 472,44 |

| mm | 12000 | |

| Probe delay | µs | from 0 to 100 |

| Frequency | МHz | from 0,4 to 20 |

| Initial pulse frequency | Hz | from 30 to 1000 |

| Operating modes | А-scan, B-scan | |

| Gain | dB | from 0 to 100 |

| Rectification |

| |

| Noises cutoff | % | from 0 to 80 |

| Gates | two independent three-level measuring gates; two additional special gates; | |

| Measurement modes | Peak, Front | |

| Reconfigurable readings in А-scan | distance by the beam, amplitude in gates, defects depth coordinates, equivalent defect dimensions | |

| Measurement resolution | inch | 0,00039 |

| mm | 0,1 | |

| Defect alarm | sound, light, visual | |

| Setups quantity | 100 | |

| Languages | English, Russian, Chinese (additional languages are possible to the customer's order | |

| Units | SI system units | |

| Communication with PC | USB port | |

| Battery | storage battery Hi-MH 12V/2500 mА×h | |

| Operation time from the battery | hour | at least 8 |

| Power supply from AC mains | alternating current single-phase mains, 230 V, 50 Hz | |

| Screen | color TFT | |

| Screen size, W x H | inch | 4,33 x 3,346 |

| mm | 110 x 85 | |

| Screen resolution, W x H | pixel | 320 x 240 |

| А-scan size, W x H | pixel | 320 x 200 |

| Overall dimensions | inch | 9,72 x 5,79 x 3,15 |

| mm | 247 x 147 x 80 | |

| Weight | lb | 7,717 |

| kg | 3,5 | |

| Operating temperature | ºF | from +14 to +122 |

| ºC | from minus 40 to +50 | |

| Protection from environmental impacts | IP 65 according to GOST 14254 |