The systems of OKOSCAN-73HS family can be mounted on different chassis depending on end user`s requirements. A railway car or a hi-rail truck with truck bed will allow using large monitors and comfortable conditions for operators` work which is essential during continuous inspection of large railway track areas. Usage of hi-rail trucks is the most universal option because it allows to start and finish inspection at any rail/road crossing. This helps to plan inspection in the areas with busy train traffic.

Pickup off-road hi-rail vehicles have the same possibilities. Their only feature in comparison with trucks is smaller space for installation of large screens, smaller tank volume for contact liquid and less comfortable conditions for operators` work. Nevertheless, this option is economic and might be perfect for performing inspection on small areas located on significant distances.

Depending on customer`s requirements, the System can be equipped either with high-speed electronics OKOSCAN-73HS to ensure the maximum inspection speed of 40-60 km/h (depending on the modification) or with more economic option OKOSCAN-73MS which ensures inspection speed of up to 20-25 km/h.

No matter the chosen chassis or electronics, OKOSCAN-73HS/MS System ensures continuous ultrasonic rail inspection with full inspection results recording and detection of all the dangerous defects in accordance with such standards as EN 16729, AREMA, etc.

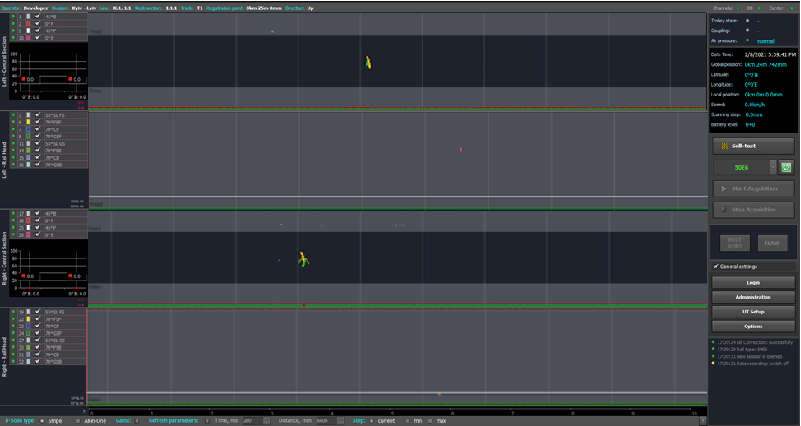

Real-time display of the test results

The System provides inspection results data in real-time (in few modes of B-Scan and A-Scan) and informs the operator about the parameters of inspection quality, such as acoustic coupling, ultrasonic wheels position relative to the rails, etc. The operator has a possibility to promptly correct ultrasonic position of wheels by controlling relative electric actuators of each wheel from the remote (for instance in curves).

All inspection data (together with settings and reliability parameters) is stored in the database, which provides wide opportunities for their filing, analysis and general monitoring of the railway track condition.

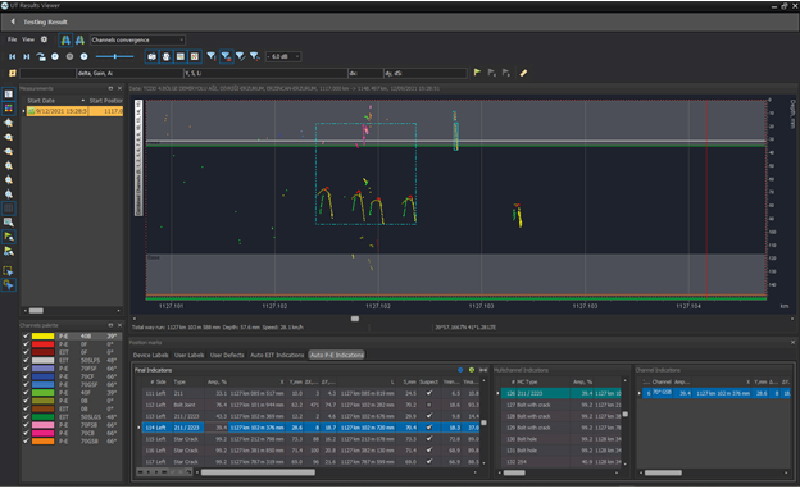

Automatic recognition of the indications, caused by the detected defects and track elements.

Intelligent machine analysis program for OKOSCAN-73HS/MS

A special software module of intelligent machine analysis was designed for OKOSCAN-73HS/MS in order to facilitate the analysis of large volumes of inspection data. The program analyzes the acquired testing data, dropping the inevitable noise spots and then builds and provides the operator with a list of suspect indications, assigning them the appropriate codes according to UIC 712R or other defect classifier. Therefore the operator only has to confirm or deny the System`s conclusion conveniently switching from one indication to another. Further, the System generates few types of reports depending on the end user`s requirements.

OKOSCAN-73HS/MS software development perspectives

We plan adding to the System’s software a feature of exporting the discovered indications to a file of navigation tags, which can be viewed on a smartphone. The location of defects relative to the inspector’s position can be observed in a real time. It will significantly facilitate the confirmatory and in-depth testing using ultrasonic inspection trolleys and manual flaw detectors.