Ultrasonic rail flaw detectors from the UDS2-7X product line

Hand-pushed ultrasonic rail flaw detectors UDS2-73 and UDS2-77

The intermediate link in the railway track quality management system (in terms of ultrasonic inspection) is rail testing using hand-pushed ultrasonic trolleys, also known as single-rail and dual-rail flaw detectors. This is the most common class of equipment used on railways worldwide. Hand-pushed flaw detectors, such as the UDS2-73 and UDS2-77, are used for confirmatory inspections following high-speed ultrasonic rail testing or for primary inspections of small track sections, tight-radius curves, station tracks, and other areas where high-speed systems are impractical or ineffective.

Dual-rail flaw detector UDS2-73

Single-rail flaw detector UDS2-77

Features of the UDS2-73 and UDS2-77 Flaw Detectors

Hand-pushed ultrasonic flaw detectors can be either single-rail or dual-rail. Single-rail models, such as the UDS2-77, are ideal for confirming individual defects, as they require only one operator, who can quickly remove the trolley from the track in case of an approaching train. Dual-rail flaw detectors, like the UDS2-73, are more convenient for continuous inspection of small track sections.

Search Systems of UDS Flaw Detectors

The UDS family of flaw detectors can be outfitted with one of two search systems: a sliding system or a wheel-type system (with immersion ultrasonic probes).

Wheel-type immersion system – the «wheel probe»

Sliding search system (SL)

Each system has its own set of advantages and disadvantages. One of the primary benefits of sliding systems is their ability to automatically position ultrasonic probes on the rail surface. This ensures consistently stable testing sensitivity, regardless of variations in the trolley's inclination. Additionally, sliding systems eliminate the need for operators to manually adjust probe angles, making them more user-friendly. However, these systems do have a downside—over time, the ultrasonic probes experience wear due to continuous contact with the rail surface, necessitating regular replacement and recalibration to maintain accurate results.

In contrast, wheel-type systems solve the issue of probe wear by enclosing the probes within a protected wheel mechanism, meaning that only the wheel tires require periodic replacement. This greatly extends the lifespan of the probes and reduces the need for regular recalibration. However, single-rail flaw detectors that are equipped with search wheel probes (SWPs) have one notable disadvantage: the changes in trolley inclination that occur during manual operation are unavoidable and can cause fluctuations in sensitivity. This can potentially affect the consistency of the inspection. Fortunately, this issue is minimized in dual-rail flaw detectors such as the UDS2-73 SWP. These models position the SWP wheels once at the start of the inspection and then maintain the position automatically throughout the testing process. This ensures consistent sensitivity levels.

UDS2-73 SWP trolley with SWP wheels and extendable chassis.

Electronic unit of the UDS2-73 SWP

Application of the UDS2-73 SWP Flaw Detector

The UDS2-73 SWP allows for continuous ultrasonic rail testing in accordance with EN 16729 and AREMA standards. It features an extendable chassis that allows for precise positioning of the search wheels (SWP) and entry bars that enable seamless passing through switches and frogs. The flaw detector has a large, high-contrast, 10-inch display; an intuitive interface; and an ergonomic design.

The testing speed can reach up to 5 km/h. The scanning step is no more than 1.5 mm along the rail path. This provides high accuracy in assessing indication amplitudes. The UDS2-73 SWP is compatible with track gauges ranging from 950 mm to 1676 mm and can accommodate all existing railway track types.

Featuring IP65 protection against water and solid particles, this rail flaw detector operates in temperatures ranging from -30°C to +55°C, making it suitable for harsh environments. The search wheels and electronics are galvanically isolated from the rails, significantly reducing electrical interference.

Displaying Testing Results in UDS Flaw Detectors

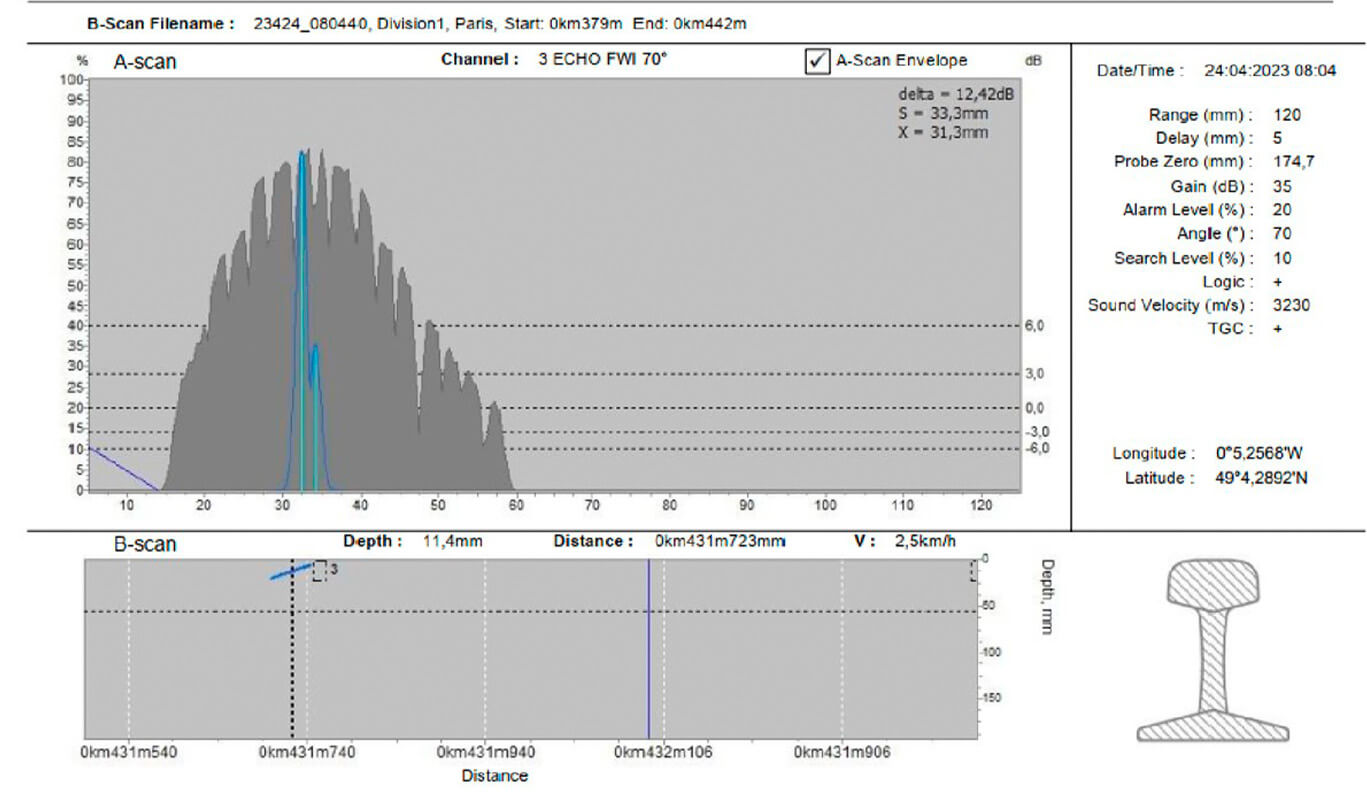

Example of how inspection data is represented in UDS2-73 SWP

The flaw detector’s software allows real-time visualization of inspection results in A-Scan, multi-A-Scan, and B-Scan formats for all channels. A dedicated mode displaying the rail profile intuitively indicates defect locations. It also supports simultaneous display of B-Scans grouped by inspection zones (rail head, central projection, etc.).

During testing, operators can mark features such as "Crossing," "Bridge," and "Bolt Hole," which are saved along with the inspection data. With a built-in GPS/GNSS system, all data is recorded with both track coordinates and real-world geolocation.

Example of a UDS2-73 SWP report

Stored data can be reviewed directly on the flaw detector or transferred to a PC via a USB flash drive. The accompanying PC software offers extensive analysis and reporting capabilities allowing users to generate various types of reports, including comprehensive evaluations of individual detected defects, detailed summaries for inspected areas, and structured reports for inspection jobs conducted over a specific period of time.

Future Development of UDS PC Software

Our development team is currently working on integrating an intelligent machine analysis module into the software, which will significantly streamline the work of data analysts. This module has already proven effective in the OKOSCAN-73HS high-speed rail inspection system.