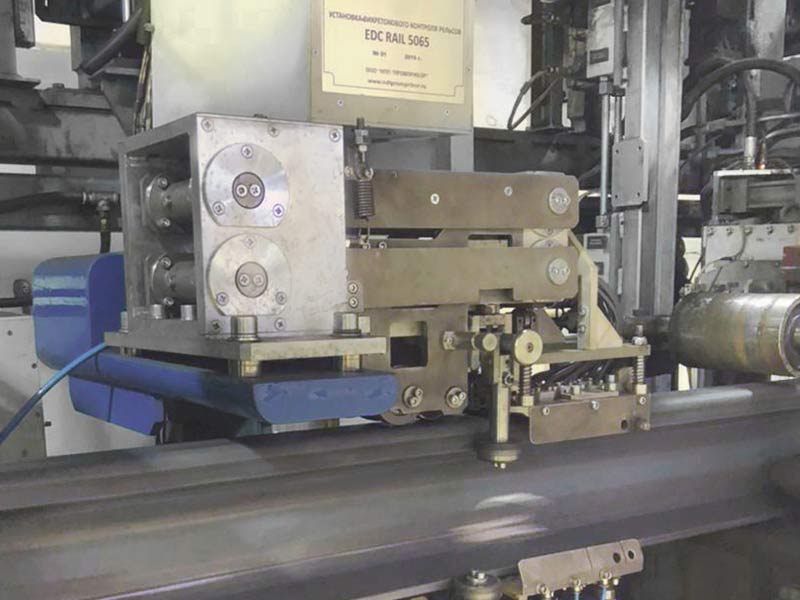

High speed ultrasonic testing of rails in a railway track

The systems of OKOSCAN-73HS family can be mounted on different chassis depending on end user`s requirements. A railway car or a hi-rail truck with truck bed will allow using large monitors and comfortable conditions for operators` work which is essential during continuous inspection of large railway track areas. Usage of hi-rail trucks is the most universal option because it allows to start and finish inspection at any rail/road crossing. This helps to plan inspection in the areas with busy train traffic.