The basic task of the eddy current nondestructive testing of railroad is to reveal head check cracking and to evaluate a damage depth in the gauge side of the rail head and the rail head running surface.

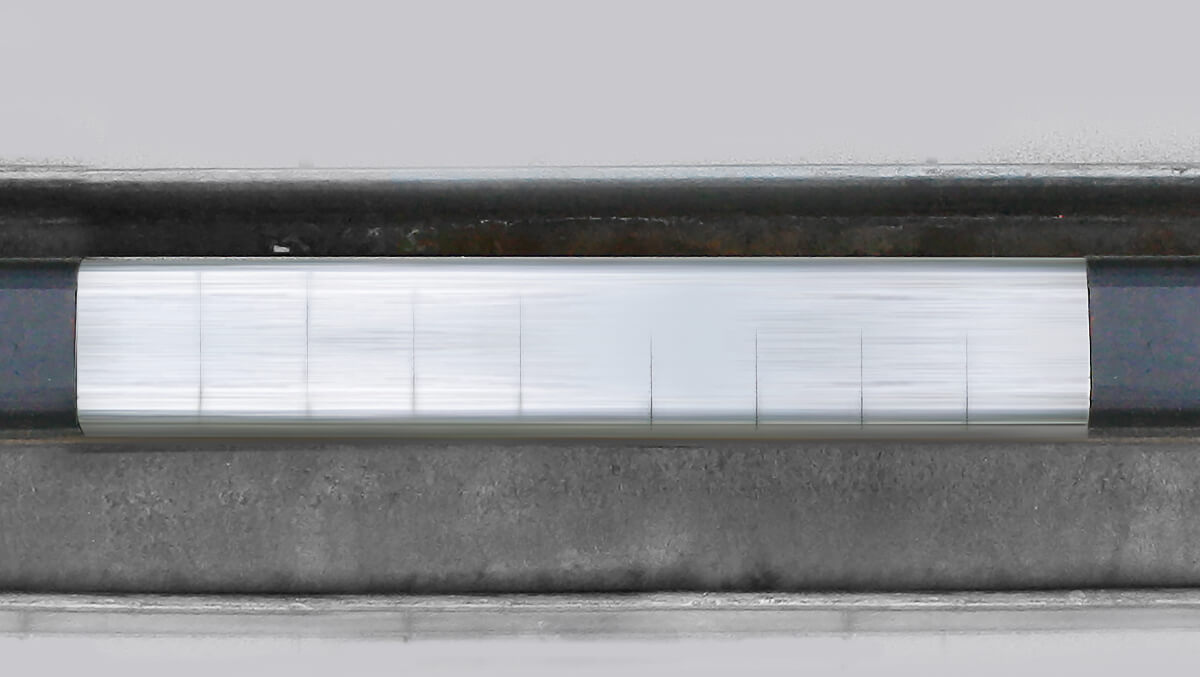

The RS 2353/1-4N-RAIL – a Rail Calibration Block made to calibrate the ETS2-77 and ETS2-73 – a mechanized eddy current rail track flaw detectors in order to assure a consistent evaluation of depth of the rail head vertical damage and take a viable decision on the application of grinding machines or necessity of repairing works on the damaged rail section. This will highly increase the economical feasibility of the track maintenance.

The RS 2353/1-4N-RAIL Calibration Block made of the rail steel has 4 Electric Discharge Machined notches of 1.2 mm, 3 mm, 6 mm and 9 mm depth induced into it. This defect type enables to dully set-up all the ECPs used together with the ETS2-77 and ETS2-73 flaw detectors.