Eddycon D Purpose

The EDDYCON D universal multi-channel eddy current flaw detector is designed to solve a wide range of tasks of eddy current flaw detection.

It is Applied in the Following Branches of Industry:

- AIRCRAFT

- testing of aeronautical engineering parts (wheel disks, covering, turbine blades, multilayered constructions, holes of various kinds etc.);

- OIL-AND-GAS

- testing of pipelines, turbine blades of gas-distributing station (GDS), pressure vessels, etc.;

- CHEMICAL

- testing of pipelines, industrial tanks, etc.;

- POWER

- testing of steam generator pipes by inner bobbin eddy current probes, collectors, etc.;

- MACHINE BUILDING

- testing of rods, wire, metalwares, forming rolls, sheet metals, etc.;

- RAIL TRANSPORT

- testing of rail components and car units (parts of wheel pair and axlebox unit, load trolley, refrigerated carriages and coaches, automatic coupler etc.).

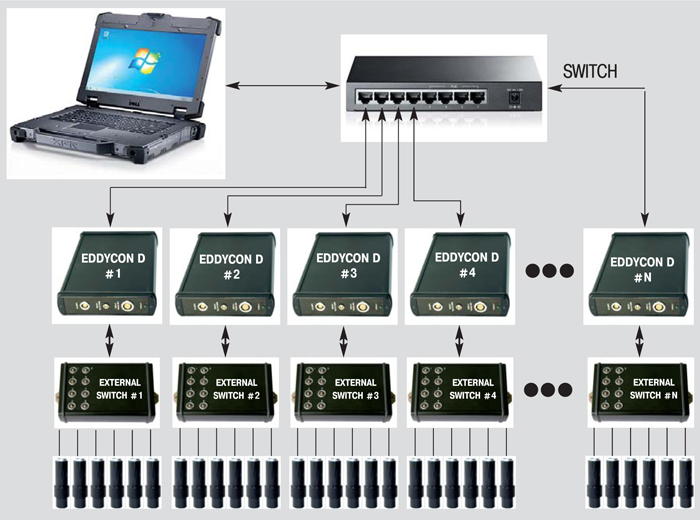

The flaw detector is an eddy current channel that using the Ethernet port is connected to stationary PCs, portable laptops or tablets and using specially configured software creates high-performance systems for non-destructive testing.

THE FLAW DETECTOR ADVANTAGES AND DISTINCTIVE FEATURES

- High performance due to the flaw detector multi-channeling;

- capability to combine several EC channels when creating the automated testing systems;

- high frequency measurement;

- data transmission via Wi-Fi channel;

- ethernet port for two-way communication with PC;

- rotary scanners connection;

- up to 2 encoders connection;

- availability of multi-functional software for flaw detection of various test objects (testing the pipe body, rolled products, wheelsets, rails, bars, wires, etc).

Figure 1. Scheme for constructing the multi-channel system

THE INSTRUMENT SPECIFICATIONS AND SERVICE FUNCTIONS

- Operating frequency setup range – from 10 Hz to 16 МHz;

- Generator output voltage (double amplitude) – from 0.5 V to 20 V;

- Adjusted gain range – 70 dB;

- "Added gain" function – 30 dB;

- Digital filtering, 3 filter types: Low-pass, High-pass, Bandpass;

- Possibility to connect a large number of ECPs when using external switches on 8, 16 or 32 channels due to the multiplexing of one physical channel;

- Software of up to 32 ECPs to one eddy current channel;

- External synchronization;

- Capability to connect and operate with the following ECPs:.

- differential ECP;

- differential ECP connected according to the bridge scheme;

- differential ECP of transformer type with grounded centerpoint;

- differential ECP of transformer type;

- single coil ECP;

- absolute ECP of transformer type;

- Setting up time for the flaw detector operation – not more than 1 minute.

SOFTWARE

Specially configured software for operation with the EDDYCON D eddy current channel includes:

- Program for setting up the EC channel;

- Program of testing;

- Program for reviewing the testing results.

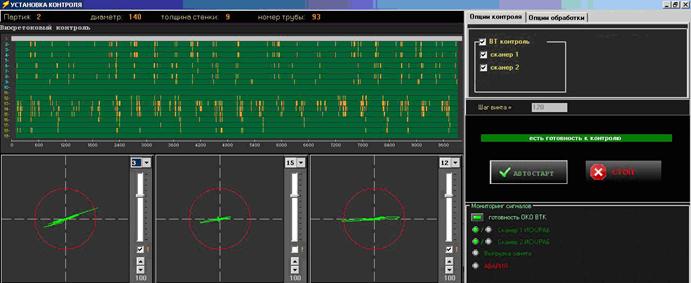

Program for Setting up the EC Channel

|

Interface example of a program for setting-up the EC channel |

This software ensures the following:

- Rapid set up of all EC channel parameters: EC probe frequency, generator output voltage, gain, filters, threshold level type, encoder, etc.

- Four independent threshold levels for automated defect triggering (ALARM) for each displayed area;

- Saving the testing setups into the PC or tablet`s memory;

- Estimating the defect depth and length;

- Channels mix.

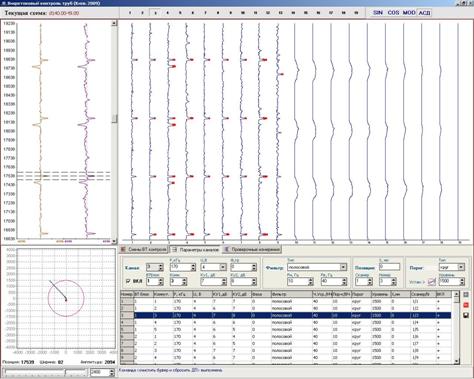

Program of Testing

|

Interface example of program of testing |

This software ensures the following:

- EC probes per channel display;

- Real-time display of EC probe information (time charts, complex plane, two-dimensional display);

- Recording the testing results into the PC or tablet memory;

- Displaying the status of mechanisms and units on the mnemoc scheme;

- Testing process control, shop mechanization (when designing automated NDT systems).

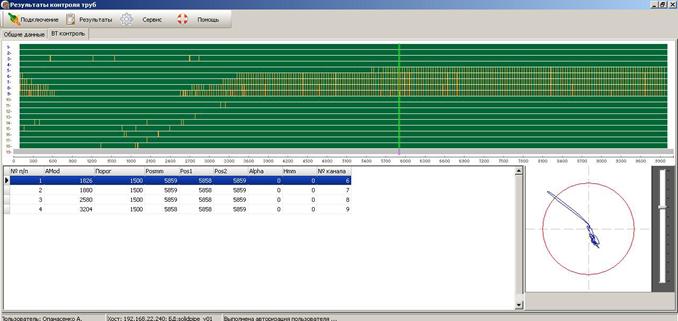

Program for Reviewing the Testing Results

|

Interface example of a program for reviewing the testing results |

This software ensures the following:

- Reviewing the testing results from the database, sorting and retrieval by various characteristics;

- Generating the testing protocols;

- Archiving the testing results;

- Reviewing the testing results from the remote PC, etc.

Overall dimensions | not more than 293 ´ 37 ´ 141 mm |

Weight | not more than 1 kg |

Number of EC probes connected to one EC channel | up to 32 |

ECP connectors | Lemo 12, Lemo00 |

Power | 2 V DC power |

Time for operating mode setup | up to 1 min. |

Warranty | 1 year |

| |

INPUTS/OUTPUTS | |

Ethernet | available |

Triggering input | available |

Encoder input | 1 axis Encoder |

| |

MAIN METROLOGICAL SPECIFICATIONS | |

Protection level | IP 64 |

Environment temperature | from – 10º to +50 ºС |

Atmospheric pressure | from 84 to 106,7 kPa |

Environment humidity | (93 ± 3) % at 25 ºС |

Full average life of the flaw detector | not less than 10 years |

| |

GENERATOR | |

Output voltage (double amplitude) | from 0,5 to 20V Peak-Peak |

Frequency range | from 10 Hz tо 16 MHz |

Synchronization type | internal, from encoder, from rotary ECP |

| |

RECEIVER | |

Gain | from 0 tо 70 dB with a step 1, 10 dB |

Added gain | from 0 tо 30 dB |

Input signal | not more than 0.5 V from Peak to Peak |

Digital filters | 3 digital filters: High-frequency, Low-frequency, Bandpass |

Non-destructive testing in the machinery industry. Bearing rollers and other cylindrical objects

Eddy current non-destructive testing equipment can be used as the basis for building of various automated systems intended for application in machinery. OKOndt engineers have developed an eddy current system for testing the cylindrical bearing rollers on the basis of the Eddycon D flaw detector. This system provides a possibility to get excellent results in detecting artificial defects of 0.75 mm length, 0.05 mm width and 0.05 mm depth with at least 10 dB signal/noise ratio.

Non-destructive testing in the railway industry. Rails

Mechanized equipment built on the basis of the Eddycon D eddy current flaw detector enables to test the rails in-service for surface headcheck cracking-type defects.

Moreover, the guideline documents regulate the procedure of the automated eddy current testing of rails in the process of their production. To solve this task, in turn, the use of eddy current flaw detectors in high-performance systems that are capable of acquiring and processing data, as well as results and commands displaying for controlling the mechanics in real-time mode becomes a clue.

Functional capabilities of the Eddycon D eddy current flaw detectors allow to build systems of a similar type by increasing the amount of flaw detectors for reaching the required performance.

Non-destructive testing in the aircraft industry. Wheels

Eddy current method is used to perform a high-performance non-destructive testing of the aircraft wheels made of non-magnetic materials (aluminium and magnesium alloys) with complex profile. Defects with the following parameters can be detected: length - 1.5 mm, width - 0.1 mm and depth - 0.76 mm, that is regulated by the normative documents of majority of the world aircraft wheels manufacturers.