INTENDED USE

Durability and reliability of rails in-service play a decisive role in railroad industry that is due to the fact that the development of the defects and breach of strength characteristics of the rails can result in their breakage or even lead to crashes. Operation of rails within many years has shown which types of defects are mainly developed in them (see UIC Code 712 R) and, of course, it can have a crucial effect on the railroad traffic safety.

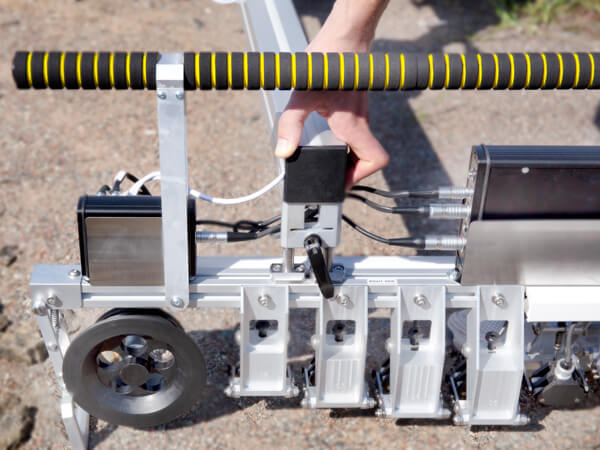

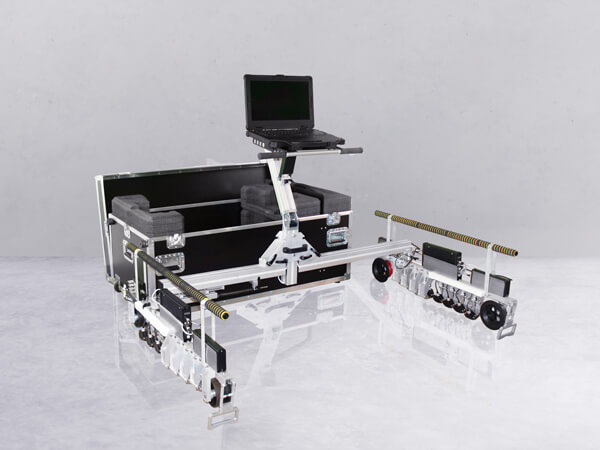

OKOndt GROUP, in order to provide for the monitoring procedure, as well as to evaluate the railway track rails condition, has released 16-channel double rail eddy current flaw detector ETS2-73.

Eddy current double rail flaw detector ETS2-73 refers to the mechanized scanning devices designed for manual testing by the eddy current method to detect surface cracks.

ETS2-73 provides the eddy current testing of the rail head running surface and gauge corner for the following types of defects in accordance with the UIC 712 R listing:

- transverse fatigue cracks - squats and headchecks (UIC - 211),

- quenching cracks (UIC - 2223),

- delaminations of the gauge corner (UIC - 2222),

- wheels sliding area "wheel burn" (UIC-225),

- etc.

APPLICATION

- ETS2-73 flaw detector allows to perform the eddy current testing of rails in accordance with EN 16729-2 Non-destructive testing on rails in track - Part 2: Eddy current testing of rails in track requirements

- Possibility to test both the rail track and rail switches

- Selective testing of particular sections of the rail track

- Testing and evaluation of the surface defects presence after grinding machines

- Testing of all major rail profiles: 49E1(S49), 54E1(UIC54), 60E1 (UIC 60) and others

ETS2-73 ADVANTAGES

- The equipment of the ETS2-73 flaw detector corresponds to ISO 15548-1 and ISO 15548-2 requirements

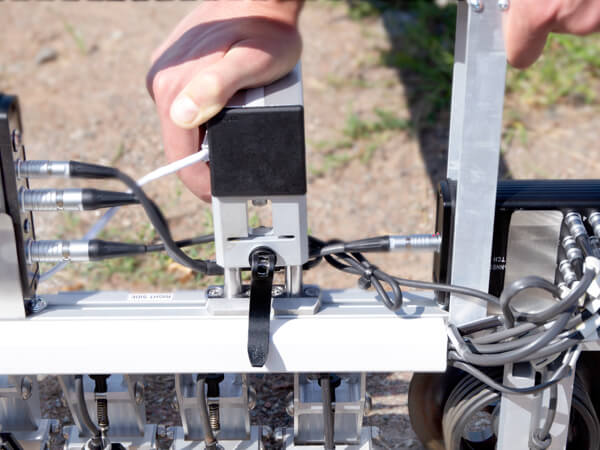

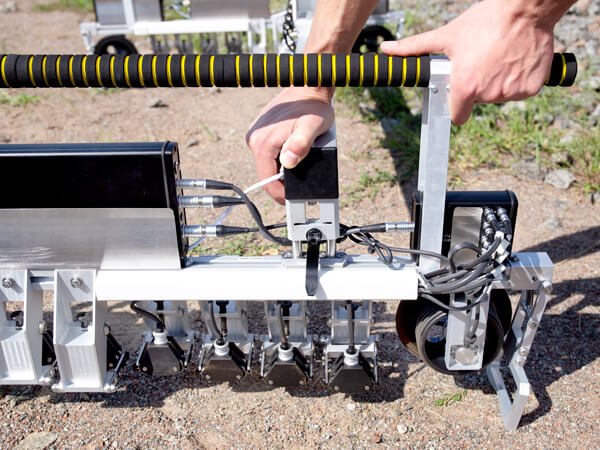

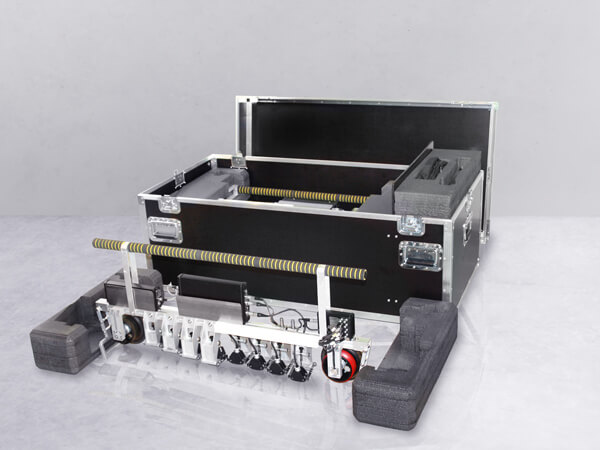

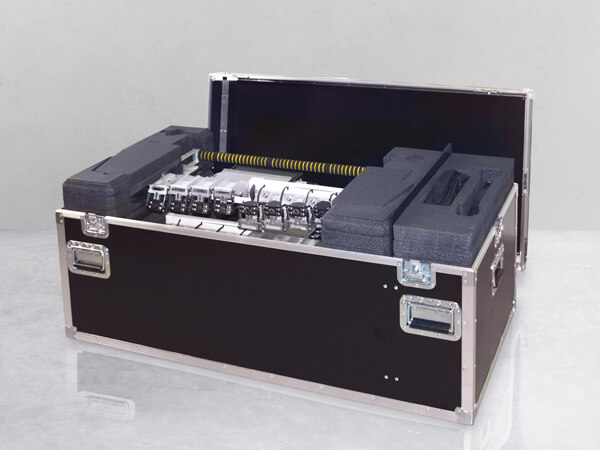

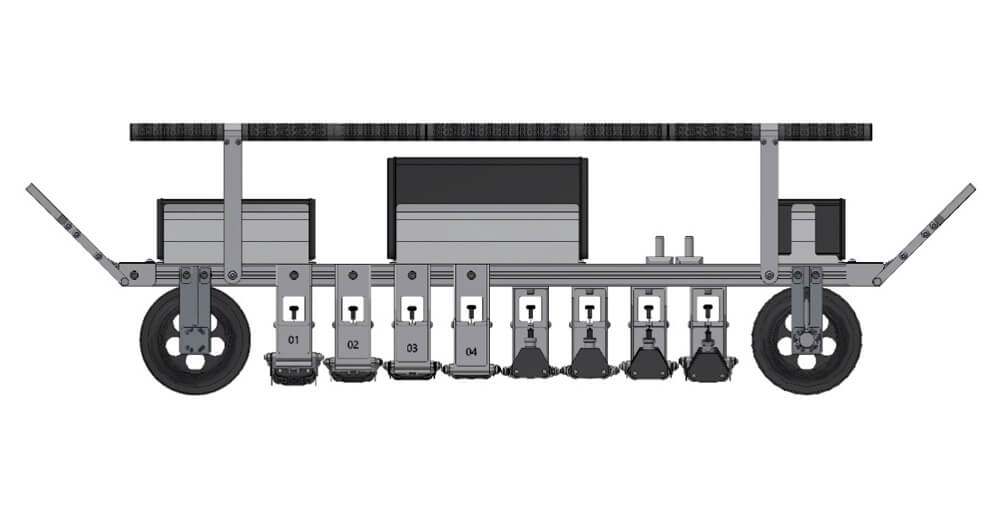

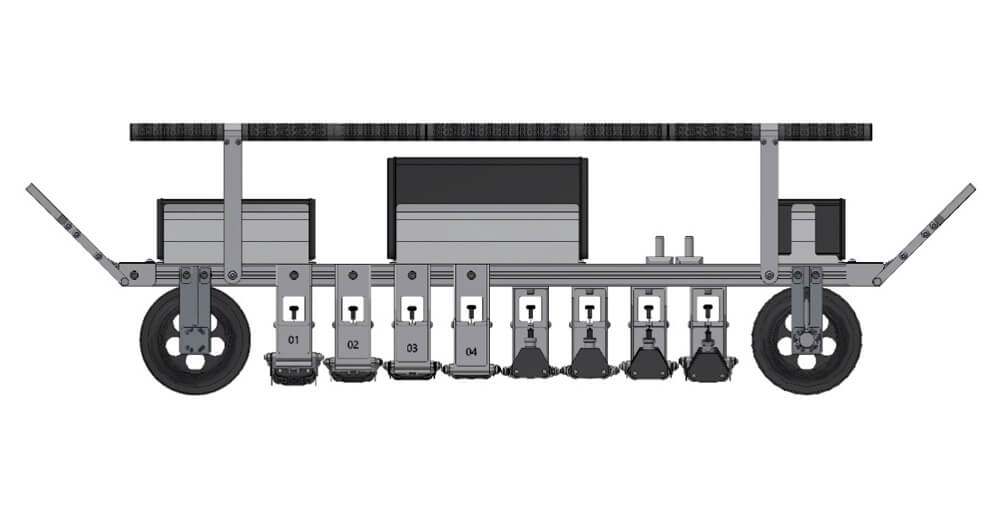

- Folding aluminum frame

- Simultaneous testing of left and right rails

- Flaw detector’s structure allows to follow the current gage of the track and adjust to it

- Specialized ECPs with protective wear-resistant covers allow to evaluate the depth of the rail vertical damage of up to 3 mm and do not care about the ECP integrity

- Use of 8 ECPs allow to perform testing of the whole rail head per one ride

- Possibility of crossing the rail bolt joints with up to 15 mm distance between the rails

- Individual spring-mounted suspension of each ECP

- Operation time from the rechargeable battery — minimum 8 hours

- Specialized software to perform setting, testing and view the test results.

Specialized software of the ETS2-73 flaw detector

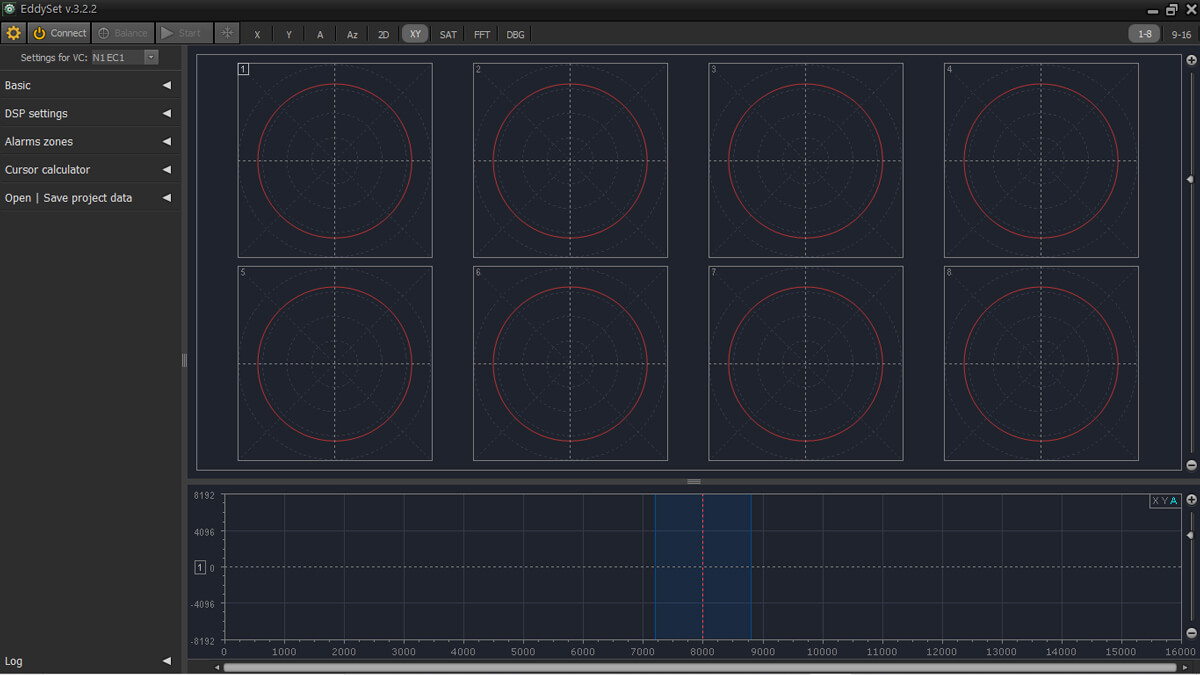

EddySet program for setting of the eddy current channels of the Eddycon D

- Fast setting of the Eddycon D’s eddy current channels – frequency, generator’s voltage, gain, filters, threshold level etc.

- Building of the calibration curves and creation of settings for a vertical damage depth evaluation.

- Saving of the settings in the PC’s memory.

Specialized software of the ETS2-73 flaw detector

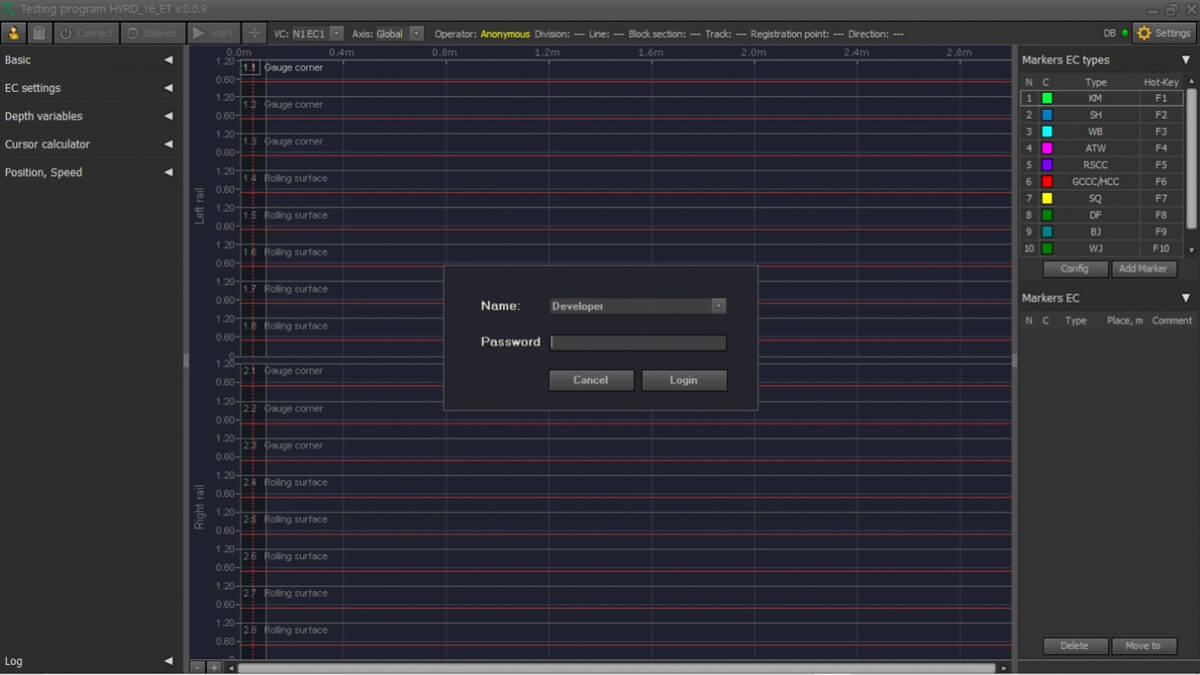

ETS2_73_ET program for testing

- Signals display from ECPs per every channel.

- Signals display from ECPs in a real time mode.

- Different types of information display (amplitude display and defect depth display).

- Record and saving of the test results for further processing.

Specialized software of the ETS2-73 flaw detector

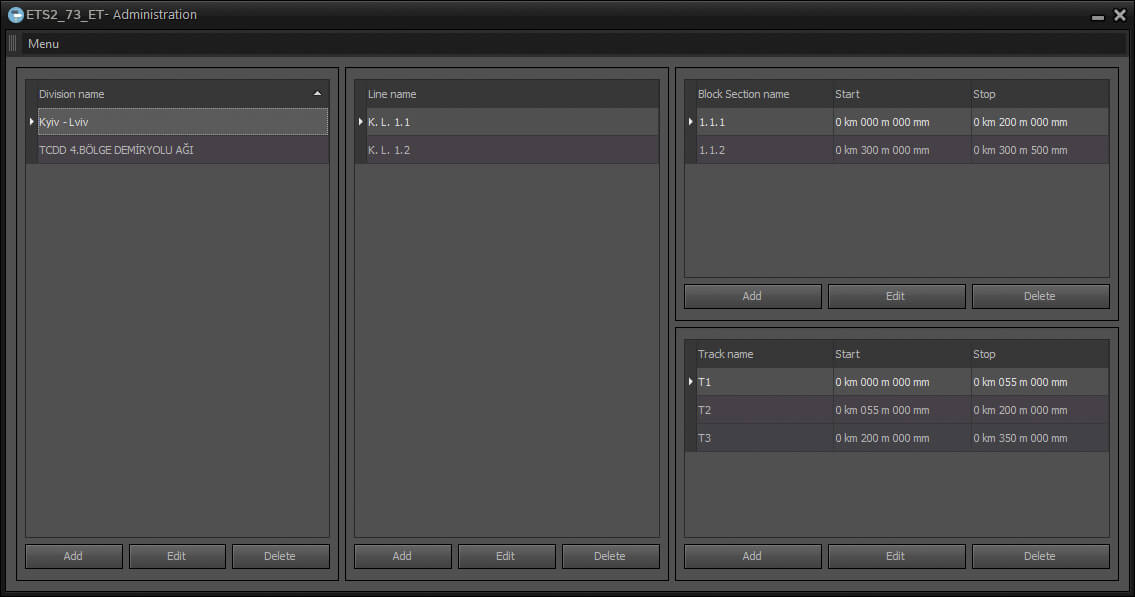

Program for creation of the track sections to provide the testing and user Administration

- Creation and administration of the track sections for testing.

- Creation and administration of the user accounts.

Specialized software of the ETS2-73 flaw detector

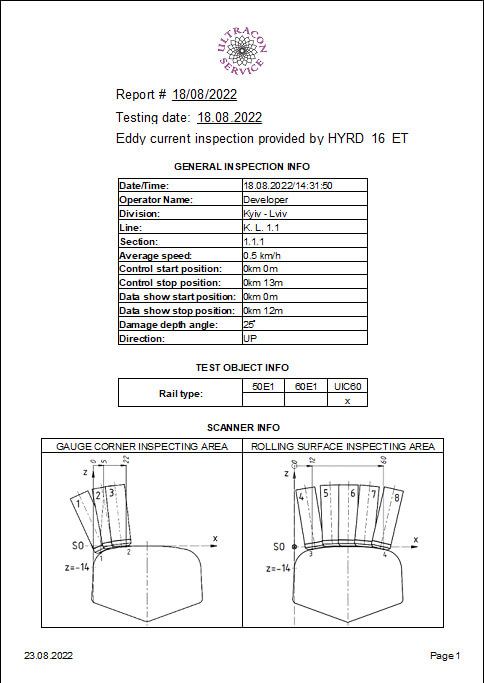

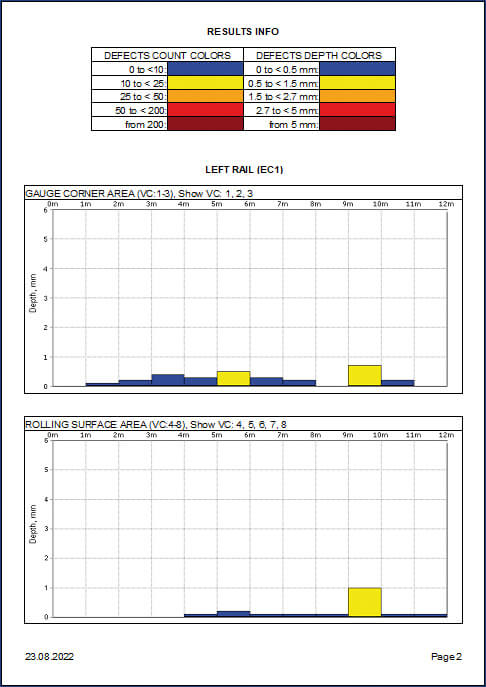

ETS2_73_ET_Result program for test results data analysis

Eddy current flaw detector Eddycon D ver.2

Operating frequencies range: 10 Hz - 16 MHz

Excitation voltage: 20 V (Peak-to-Peak)

Maximum input signal voltage: 2.0 V (Peak-to-Peak)

Amplifier 1: 0 - 30 dB with a step of 0.1 dB

Amplifier 2: 0 - 40 dB with a step of 0.1 dB

Amplifier X: 0 - 30 dB with a step of 0.1 dB

Amplifier Y: 0 - 30 dB with a step of 0.1 dB

Signal phase: 0° - 359° with a step of 1°

LowPass filter: FSMP. MAX/2 (1 Hz to 40 kHz)

HighPass filter: FSMP. MAX/2 (1 Hz to 40 kHz)

BandPass filter: FSMP. MAX/2 (1 Hz to 40 kHz)

Overall dimensions: 293 x 37 x 141 mm

Weight: not more than 1 kg

Power supply: 12 V DC

Industrial laptop SWELL i156

SPECIFICATIONS | |

Waterproof grade | IP65 |

OS | Windows 10 |

Display | 15.6inch IPS 1920*1080 FHD |

CPU | 8th Generation KBL-R Intel® Core™ i5-8250U |

Storage | 8GB RAM, 1 TB ROM |

DATA COMMUNICATION | |

WLAN | WIFI 802.11(a/b/g/n/ac) 2.4G+5.8G dual WIFI, BT4.2 (BLE) |

Battery | 2000mHA/7.4V +6300mHA/7.4V |

I/O port | USB3.0*3 , USB2.0*1 , ∮3.5mm standard headphone port, HDMIx1 (type-A)DB9 (RS232 or RS485) ×1SD cardx1RJ45x2(10/100/1000M self-adaption) Network card chip model 1219+I210 |

Products size | 397*271*37 mm/3300g |

SPECIFICATIONS

Product model | ETS2-73 |

Flaw detector type | manual, double rail |

Areas of testing |

|

Quantity of ECPs of the flaw detector | 16 |

Quantity of ECPs for one rail testing | 8 |

Testing speed | up to 2 m/s |

Eddy current channel | |

ECP protection from mechanical damage and wear | ceramic protector |

Signalization (ADS) | visual |

Specialized software | - setting program - testing program - results viewing program |

Time of continuous operation | 8 hours |

Data record and storage | PC’s hard drive |

Operating PC | Industrial PC with IP 65 protection class |