NO LONGER PRODUCED

UD3-71 Purpose

UD3-71 flaw detector is an ultrasonic general-purpose flaw detector which is intended for:

- manual non-destructive testing of products for detection of defects such as discontinuity and inhomogeneity of material in raw stock, finished items, in-process goods, welded, soldered, bolt, riveted and other joints;

- measurement of defects depth and depth coordinates;

- measurement of various items thickness at one-way access to them;

- measurement of signals (reflected from defects) amplitudes ratio;

- measurement of equivalent defects dimensions;

- assessment of sound velocity in sundry materials.

Flaw detector is able to test materials and products with sound velocity from 1500 m/s to 12 000 m/s.

UD3-71 ultrasonic flaw detector provides the testing of weld joints and base materials, and also thickness measurement of monometals, bimetals in correspondence with the regulatory documents requirements in various industrial sectors.

UD3-71 Flaw detector advantages

Min. instrument dimensions – no more than 200x100x110 mm – assure high instrument ergonomics and operation simplicity.

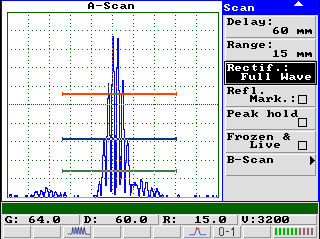

- Various A-scan display forms: RF/full wave/+half wave/-half wave;

- Dynamic change of generating path characteristics depending on the switched-on frequency filters;

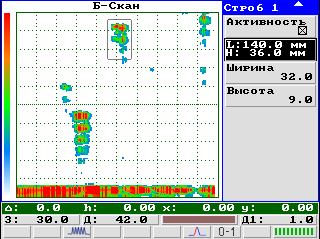

- Information display forms: А-scan, B-scan, orthogonal views, corrosion map;

- USB slave;

- Flaw detector can be operated at the ambient temperature from minus 10 to +45 °С;

- Flaw detector case protection level from solid bodies and water penetration corresponds to IР65;

- Easy removable battery;

- Flaw detector is also resistant to ionizing radiation impact and is meant for operation in increased humidity conditions;

- Availability of two independent measurement gates with the defects alarm system (sound and light) by each gate. At the same time, every gate has:

- Three going-off levels: "ACCEPTANCE"; "REGISTRATION"; "SEARCH" are marked on flaw detector screen in "RED", "BLUE" and "GREEN" color. The colors of light ALARM by every gate correspond to them. Application of three-level gates makes it possible to estimate the risk of detected defects;

- the sound alarm going-off level is set up by an operator by a specific gate;F

- the mode (when the preset level is transcended or not) is set up by an operator for every gate independently.

When using three-level gates it is possible to register echo-signals at different levels relative to the acceptance level. It will permit to record echo-signals from developing defects and monitor defects in the program of testing results viewing what is necessary for carrying out ultrasonic testing (UST) of important objects. Three-level gates as well as convenient sound and light defect alarm system allow to assess the detected discontinuity dimensions quickly and qualitatively.

Time control gain (TCG) mode

TCG level is set up in the point grid connected by linear sections, i.e. it is possible to set sundry TCG curve forms – piecewise-linear, step etc. TCG level corresponds to the signal attenuation in the given point relative to the set gain value. This option allows to test long-length items and items made from materials with great attenuation, it is also used for sensitivity setup when testing weld joints with wall thickness of more than 12 mm.

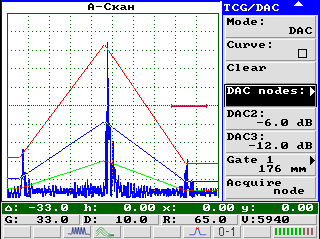

DAC amplitude curves mode

DAC mode is an alternative to TCG mode and enables to plot the curve which connects points (corresponding to signals peaks) on the screen, and also to plot up to 2 additional curves which is the preset value dB distant from the base one. DAC mode also allows quick and convenient TCG curve plotting.

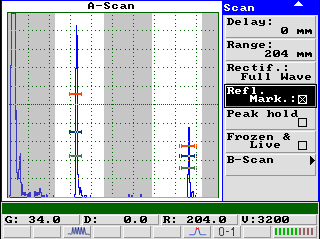

«REFLECTIONS MARKING» mode

"REFLECTIONS MARKING" mode helps to imagine the detected defect location in the testing item in the same direction as ultrasonic beams (straight and multiple-reflected beam).

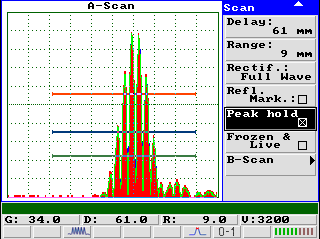

«PEAK» mode

"Peak" mode is indispensable during small defects search, operation in unstable acoustic coupling conditions. Upon that, the current signal value is displayed on the screen concurrently with the max. signal envelope of all observable echo-signals (displayed in red color). This mode is applied for max. echo-signal amplitude determination and conditional length estimation. It can be used for testing results registration both for rejected and in-order items, what will confirm the presence or absence of defects throughout the whole scanning perimeter. Thus, "Peak" mode application increases results reliability and reduces testing time.

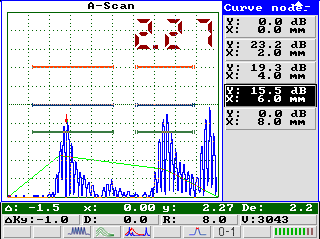

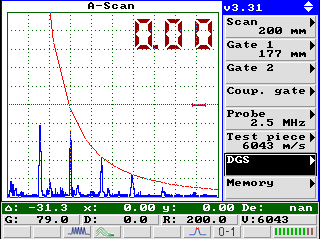

Measurement of equivalent defects dimensions (DGS diagrams)

UD3-71 flaw detector distinctive feature is the measurement of equivalent defects dimensions.

Using DGS diagrams UD3-71 flaw detector enables to measure equivalent defects dimensions in the range from 0,8 to 20,0 mm (equivalent defect diameter) with relevant error which does not exceed 15 %.

Availability of the algorithm (built in flaw detector software) of automatic plotting of DGS diagrams for various probes types makes it possible to analyze the received data quickly and qualitatively and determine equivalent dimensions of the detected discontinuities with their further registration. To save the time which is used for the instruments setup, UD3-71 instrument software contains the function of automatic TCG curve plotting by DGS diagram plotted for a specific probe.

RF signal display

To measure precisely the item thickness and defects coordinates, the undetected RF (radio frequency) signal is used what enables to assure the measurement resolution of 0,01 mm. Two modes of the point selection on the signal oscillogram by which the measurements are taken (automatic and manual) are provided in the instrument.

Special program interface mode

This mode is applied for solving special-purpose tasks. For example, when testing various single-type parts or when the part has many testing area. For solving this task "Special program interface" system is used in UD3-71. The necessary standard setups and program interface of "Special program interface" enter flaw detector from PC. The input setups are protected from illegal change by NDT inspector (operator).

Mode of connection to PC

is essential for data transmission from the flaw detector memory to the computer memory and vice-versa. It is used for transmitting "А-scans" and "B-scans" to PC for reports creation on the basis of testing results or databases. If required, the user can input setups for specific testing types in flaw detector from PC via in-built USB port what considerably reduces the time of flaw detector preparation for testing execution.

ADDITIONAL SOFTWARE

Ultra UDх-7х - the program intended for processing testing results of UD3-71 ultrasonic flaw detector and serves for functionality extension and increase of instrument operation comfort. The present program assures operation with the data stored on PC

Memory elements operation enables to perform the following functions:

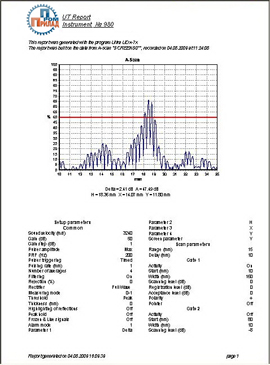

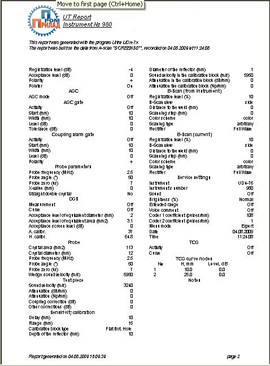

Report printing: A-Scans and B-Scans

Ultrasonic flaw detector UD3-71 + TOFD version

Flaw detectors for ultrasonic testing of rails and welds

Set of ultrasonic transducers for testing aircraft components while sing ultrasonic flaw detectors Sonocon B and UD3-71

| parameters | units | values |

| Max. scan range | inch | 236,22 |

| mm | 6000 | |

| Min. scan range | inch | 0,039 |

| mm | 1 | |

| Velocity in the material | inch /µs | from 0,0025 to 0,0375 |

| m/s | from 1000 to 15000 | |

| Scan delay | inch | 236,22 |

| mm | 6000 | |

| Delay (in the wedge) | µs | from 0 to 100 |

| Frequency | МHz | from 0,4 to 20 |

| Initial pulse frequency | Hz | from 30 to 1000 |

| Operating modes | А-scan, B-scan | |

| Gain | dB | from 0 to 100 |

| Signal detection | radio signal (without detection) full wave positive half-wave negative half-wave | |

| Noises cutoff | % | from 0 to 80 |

| Gates | Two independent three-level measuring gates Two additional special gates | |

| Measurement modes | Peak, Front | |

| Reconfigurable readings in А-scan | distance by the beam, amplitude in gates, defects depth coordinates, equivalent defect dimensions | |

| Measurement resolution | inch | 0,00039 |

| mm | 0,01 | |

| Defect alarm | sound, light, visual | |

| Setups quantity | at least 100 | |

| Languages and interfaces | English, Russian, Chinese (additional languages are possible to the customer's order) | |

| Units | SI system units | |

| Connection to PC | mini-USBt | |

| Battery | storage battery Hi-MH 12V/2700 mА×h | |

| Operation time from the battery | hour | at least 8 |

| Power supply from AC network | single-phase network 230 V, 50 Hz | |

| Screen | color TFT | |

| Screen size, W x H | inch | 2,756 x 1,969 |

| mm | 70 x 50 | |

| Screen resolution, W x H | pixel | 320 x 240 |

| А-scan size, W x H x D | pixel | 320 x 200 |

| Overall dimensions | inch | 8,27 x 3,94 x 4,33 |

| mm | 188 x 107 x 78 | |

| Weight | lb | 1,764 |

| kg | 0,8 | |

| Operating temperature | ºF | from minus 22 to +122 |

| ºC | from minus 30 to +50 | |

| Protection from environmental impacts | IP 65 according to GOST 14254 |

| Electronic unit of the ultrasonic flaw detector UD3-71 | 1 pc. |

| Piezoelectric transducers (M8) | |

| П111-2,5-К12-003 | 1 pc.* |

| П121-2,5-50-М-003 | 1 pc.* |

| Cable connection PEP / electronic control unit (M8 × 2BNC) | 1 pc.** |

| Cable connecting the PC / electronic control unit (USB × USB mini) | 1 pc. |

| Synchronization cable | 1 pcs. *** |

| Automatic charger Friwo | 1 pc. **** |

| Head phone | 1 pcs. *** |

| Processing software | |

| Processing software: testing results on a PC | 1 pc. |

| User's Guide for Software: software for processing diagnostic data on a PC | 1 copy. |

| Manual UD3-71.23535778.03.01.05RE | 1 copy. |

| Manual Friwo.23535778.001 RE | 1 copy.**** |

| Case for spare parts and accessories | 1 pc. |

| Calibration certificate flaw UD3-71 | 1 copy. |

* - Can change (or supplemented) by order of the consumer in the attached probe nomenclature.

** - On delivery type converter cable P112 constructively can be included in probe.

*** - Supplied upon request of the consumer.

**** - Type of charger may change.