The UDS2-73 SWP ultrasonic rail flaw detector is intended for continuous, mechanized rail testing of railway tracks, including turnouts (crossings and frogs), at speeds of up to 5 km/h. The trolley detects defects in both rails along the full length of the track and throughout the rail cross-section, except for the foot flanges. It also enables manual confirmatory testing of specific rail cross-sections and weld joints, determines the parameters of detected defects, and stores all test results in non-volatile memory.

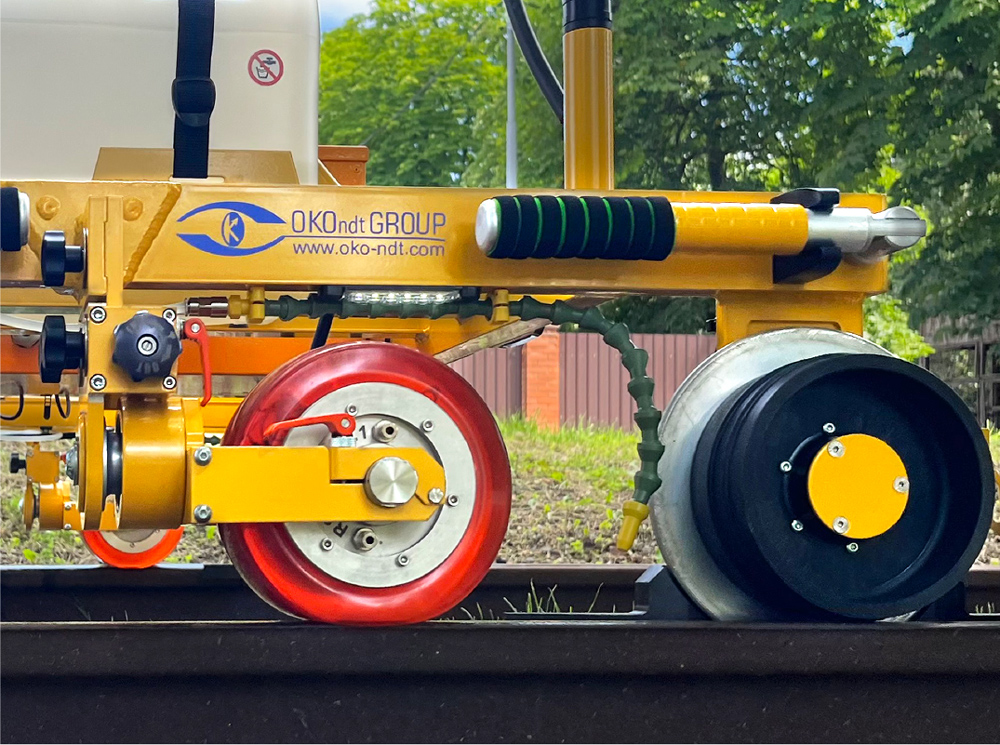

UDS2-73 (Search Wheel Probes)

The flaw detector provides for internal and subsurface defects detecting in accordance with IRS 70712:2018 (UIC 712 R), EN16729-1, EN16729-1, and AREMA.

Design of the flaw detection trolley is compliant with the requirements of EN 13977.

Quantity and type of probes: 11 pcs (00/4MHz, ±37, ±70C, ±70GS, ±70NGS, ↑↓55 SL/2 MHz).

UDS2-73 SWP flaw detector design features

- Ergonomic, light and reliable design of the flaw detection trolley ensures testing of all existing rail sizes of the track (within 950 – 1676 mm).

- Possibility to adjust in three planes the position of the electronic unit for control and visualization (screen) provides for a handy testing in the field. The electronic unit has IP65 rating according to the EN60529 standard.

- Precise positioning on the rails is ensured by the mechanical adjustment of the search wheels (SWP) in the longitudinal and transverse directions, as well as their tilt angle.

- The search wheels (SWP) are galvanically isolated from potential interference caused by the electrical potential of the rails.

Extra options

- To be able to use the flaw detector in the metro, in the tunnels and at nighttime the flaw detector’s chassis is equipped with the front and rear lights for the inter-rail space, illumination scanner-rail contact area, as well as far directional lighting.

- The flaw detector is equipped with a GPS-router to link position of the detected defects to the GPS-coordinates.

- A spare NiMH battery is available upon the customer’s request.

Key features

- Scanning the rail in one pass in one direction.

- Detection of artificial reflectors in the form of flat-bottom holes and cylindrical holes according to EN 16729-1.

- The step of sounding the rail at a testing speed of up to 5 km/h is no more than 1.5 mm.

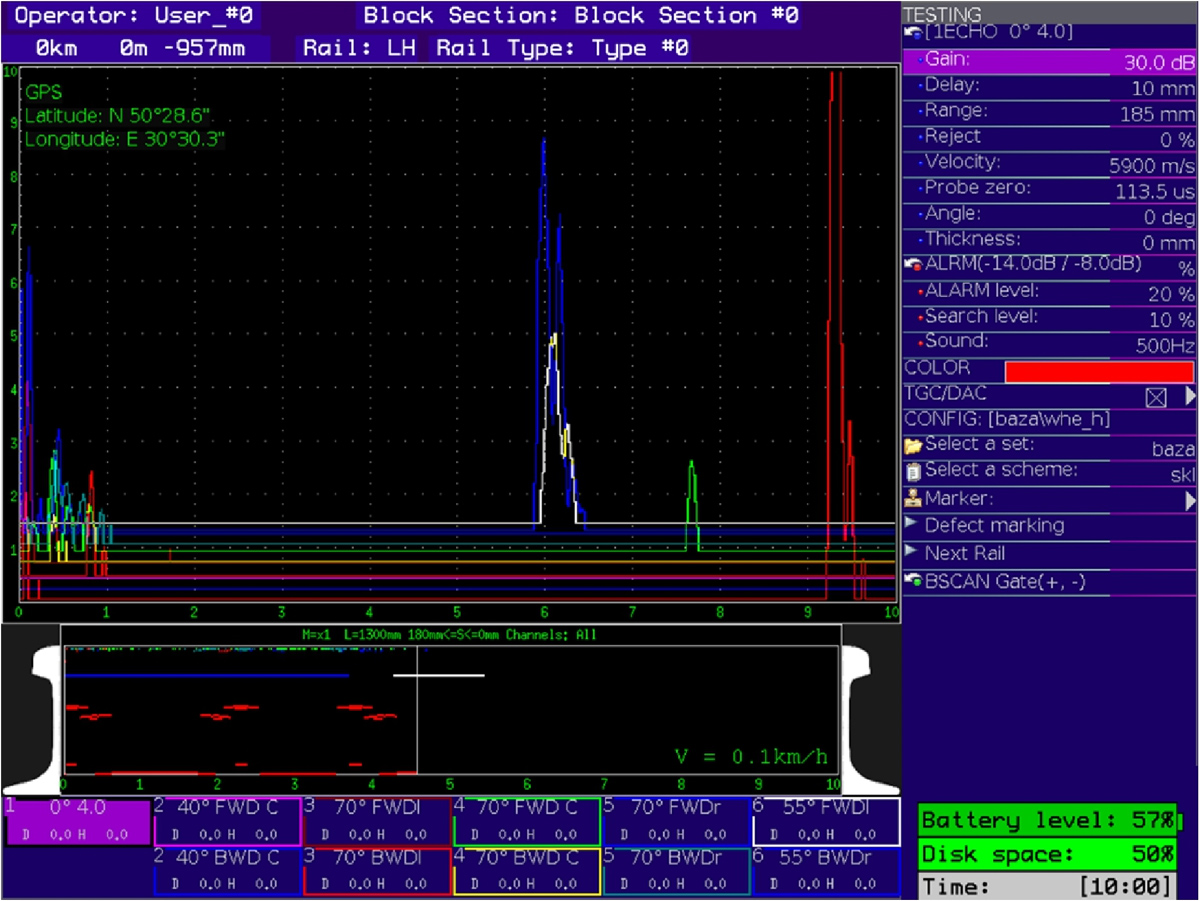

- Representation of test results in the form of A-scan, multi-A-scan, B-scan for all channels.

- Real-time display of test results in the form of B-scan.

- Data recording and saving (operator’s name, line, direction, track number, initial track coordinate, date, time, final track coordinate).

- Screenshot saving (PrintScreen).

- Saving of test results in the form of data array (B-scan) to the internal memory.

- Use of USB flash drive for transferring the test results to PC.

- Saving track coordinate (Encoder) and global coordinate (GPS).

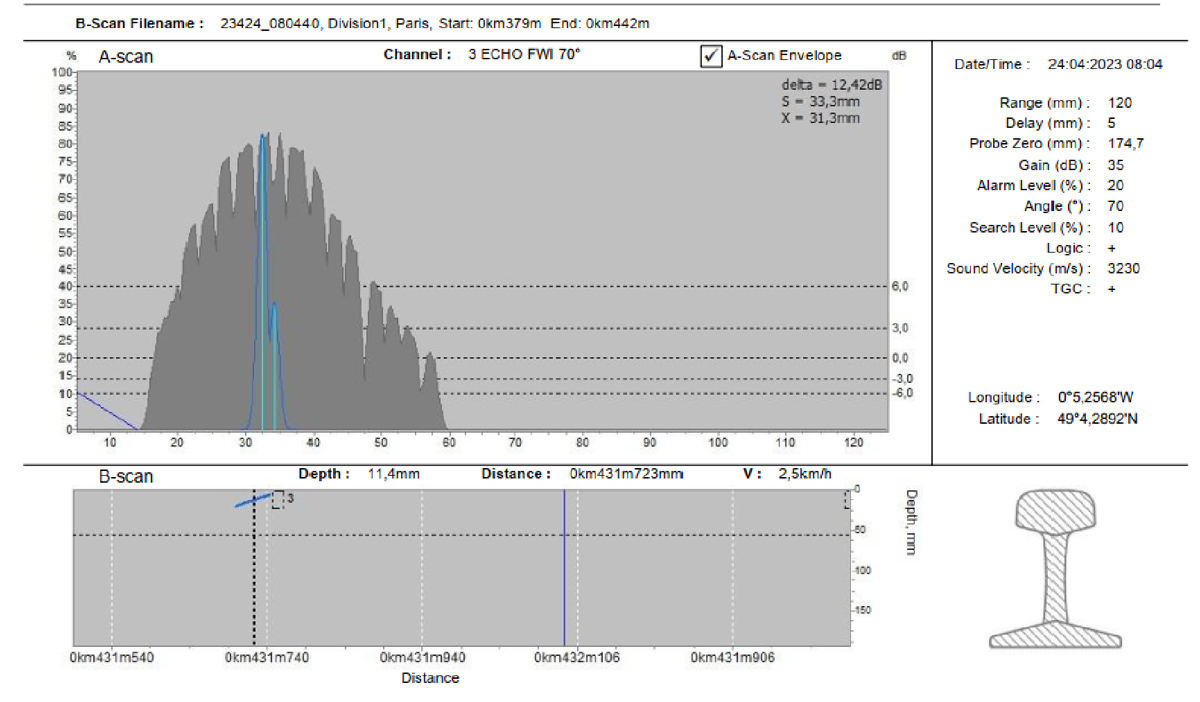

- Post-viewing of test result on the flaw detector with the possibility to measure conditional sizes of defects.

- Possibility to put the track markers (e.g. “Bridge”, “Crossing”, “Bolt hole”, etc.).

- Signaling about the presence of defects: sound, light, visual, indication of the set testing sensitivity values, defect coordinates, current track coordinate–digital on the screen built into the flaw detector.

- The flaw detector provides detection of internal defects in accordance with the following codes per IRS 70712:2018 (UIC 712 R).

- The “Rail Inspector” program for viewing and analyzing the test results on a PC is included in the flaw detector delivery set.

- The time of continuous operation of the flaw detector from a fully charged battery is at least 12 hours.

- Presence of a screen (LCD) 10'' with high resolution for high-quality display of testing results in the form of B-scan with color amplitude gradation.

- The presence of a sun-protective hood during the monitoring in sunny weather.

- The flaw detector during operation is resistant to the action of the following climatic factors: ambient air temperature from minus 30 to plus 55°C and air humidity 95%.

REPORTS

The user has access to 3 types of quick reports generated from the device menu, as well as 4 analytical reports that are generated on a remote workstation on a computer using special software "RailInspector". Report examples are given in the pictures below.

An example of one of the three types of quick report that is generated through the flaw detector menu. This example shows a multi A-scan+B-scan report.

Date/Time: 08.28.2023:07.02 |

Probe type: |

An example of one of the analytical reports created in post-processing using the Railinspector program.

Ultrasonic B-Scan + A-Scan

Test report UDS2-77 #2304333

DESCRIPTION | QUANTITY | ||

1 | Trolley’s composed of:

| 1 set. |

|

2 | UT Multiplexer unit (MUX) | 4 pcs. |

|

3 | Electronic Unit (EU) | 1 pc. |

|

4 | Protection cover for screen (EU) | 1 pc. |

|

5 | Sunlight protection | 1 pc. |

|

6 | Power Supply Unit | 1 pc. |

|

7 | Battery (Ni-MH) | 1 pc. |

|

8 | Charger device | 1 pc. |

|

9 | Headphone | 1 pc. |

|

10 | Search wheel (SWP) complete with the following probes (for one SWP):

(3 crystals in one housing) - 2 pc;

| 2 pcs. | The number of probes in the search wheel and the input angles can be changed. This is done at the request of the customer. |

11 | Contact fluid supply system:

| 1 set |

|

12 | Connecting and service cables as part of:

| 1 set |

|

13 | A set of manual UT probes:

| 1 set |

|

14 | Integrated lighting of the inter-rail space and scanners | 1 set |

|

15 | Integrated main directional lighting (on a bar) | 1 set | Option. Not included in the basic set |

16 | Special calibration unit, rail fragment with artificial defects according to EN16729-1, with SWP fixation and handling device. | 1 set | Option. Not included in the basic set. |

17 | Installation for measuring the velocity of ultrasound: - Speed measuring device; - WP-0-4-M-01 UT probe; - BNC-M5 cable | 1 pc. |

|

18 | Hand pump for filling SWP | 1 pc. |

|

19 | USB flash card (16 Gb) | 1 pc. | + set of technical and operational documentation |

20 | Box for storage and transportation with rollers | 1 pc. |

|

21 | A set of technical and operational documentation includes:

| 1 set |

|

22 | Calibration certificate | 1 pc |

|

23 | Spare Parts: | ||

23.1 | Polyurethane casing for measuring wheel | 2 pcs. |

|

23.2 | Tube for liquid with nozzle (Nozzle) | 2 pc. |

|

23.3 | Battery (Ni-MH) | 1 pc. | Option. Not included in the basic set |

23.4 | Tools for maintenance | 1 set |

|

23.5 | Fuses | 5 pcs. |

|